When it comes to felling trees with a chainsaw, careful preparation is key. If you think in advance about how you will fell trees and what equipment you will need, you not only guarantee your safety, but also make it easier for yourself further work for cleaning fallen trees. First, make sure there are no major obstructions in the work area (such as power lines, roads, or buildings). If the area of forest chosen for work has a road or people frequently visit it, place warning signs.

2. Determine the direction of felling the tree

Then carefully inspect the tree to determine the direction in which it will be felled. What do the branches look like and how do they grow? Also, consider the direction of the wind. If you cannot determine the natural direction of felling, move away from the tree and check its slope using a protractor (for more information, see section " Interesting facts"). Clear the area under the tree in the intended direction of felling. In addition, clear an area with a radius of about 45 degrees on both sides of the base of the tree to allow for movement.

3. Clear the trunk of branches

After clearing the area, placing warning signs, selecting a felling direction, and an escape route, make sure there is enough fuel in the saw's fuel tank to get the job done. It's time to cut off all branches and twigs that might interfere with cutting down the tree. It is safest to prune using the pull sawing technique ( bottom guide bar) from top to bottom.

4. Choose your sawing technique

After clearing the trunk of branches to shoulder level, you can begin cutting. In this case, two conditions must be met: firstly, the cut must have equal thickness and suitable size throughout; Secondly, it is necessary to use a guide wedge or felling blade in a timely manner so that the barrel does not jam the saw guide bar. The cutting technique depends on the size of the tree and the inclination of the trunk, as well as the dimensions of the chain saw. Below you will find information on various felling techniques. You can choose the method most suitable for your conditions. /link to the corresponding paragraph of the section “Working with a chain saw”/

5. Checking the tree for diseases

If you notice that the wood of the selected tree is faded and has soft texture, or the lower part of the trunk is swollen or has signs of disease, work must be done with extreme caution. This means that the tree is affected by rotting, which leads to softening of the wood. If you notice such signs, fell only in the natural direction. When in doubt, use a winch. Usually less susceptible to rotting upper part trunk, so another solution may be to place the cut high.

6. Tool selection

When felling trees, you can use special felling tools. The choice of tool depends on the size of the tree. For small trees Special equipment is usually not required. You can fell the tree by hand or with a long pole. Using a guide wedge, you can obtain more force than using a felling blade. In particular difficult cases you can use a rope with a winch. This is the safest and powerful way, used for felling trees. More information For information about tools, see the "Interesting Facts" section.

Determining tree height

- Take the stick in your outstretched hand so that the length of the stick is equal to the distance between your hand and your eyes. Hold the stick vertically so that your eyes, hand, and top end of the stick form the vertices of a right triangle.

- Point your hand with the stick at the tree and stand from it at a distance at which the length of the stick is visually equal to the height of the tree. If the tree is leaning, you will get a more accurate result from a position in which the tree is not leaning towards or away from you.

- At this point, the distance between you and the tree is equal to the height of the tree.

Miracle shovel is a real invention and assistant for the gardener. Recently, gardeners and gardeners have often begun to use miracle shovel for digging earth. Now, on almost every personal plot there is such a tool. Moreover, some models of such tools have become quite popular among summer residents. Working with such a device significantly reduces physical activity. At the same time, with its help, the processing of the earthen area is carried out almost 3 times faster.

Pros and cons of miracle shovels

The miracle shovel can be called universal garden tool. However, he not only has positive properties, but also negative. The device has many advantages:

- Thanks to such a shovel, a person works in the garden or vegetable garden with reduced physical activity;

- The wide span of the forks makes it possible to significantly speed up the process of cultivating a plot of land of any size;

- Working with the device is easy and simple;

- With the help of a miracle shovel you can even process heavy types soils;

- High reliability and durability of the tool.

It is also worth paying attention to the disadvantages of the miracle shovel:

- For maximum results of work using this device, the worker’s weight must be at least 80 kilograms;

- If a shovel breaks, problems with repair may arise;

- It is impossible to make a figured dig with this tool;

- It is impossible to dig holes.

However, this gardening tool can be used to cultivate any type of land. Miracle shovels can be used for loosening and digging soil for subsequent planting of vegetables. Thus, devices with forks that can dig the soil to a depth of 15 to 25 centimeters can be used to prepare the soil for planting some vegetables:

- corn;

- and other crops.

More tender plants( , ) are planted not with seeds, but with seedlings. In this case, the holes should be dug with a regular garden shovel. It is worth noting that it is impossible to work a miracle with a shovel in the garden. With its help you cannot dig up trees or dig a hole, so the work should be carried out with a classic shovel.

Important! This device can be effective if land plot has an area of 0.5 acres or more. At small sizes It is better to cultivate the soil using a bayonet shovel.

The main design elements of a miracle shovel

The miracle shovel not only performs its direct function - digging the earth, it also loosens and breaks clods of earth. The design consists of two strips with pins. They are movably connected to each other. Sometimes the device may consist of one such strip.

Some manufacturers produce models that have a back stop. This shovel is designed to make work easier when digging dense, heavy soil. So the miracle shovel is more like a double pitchfork.

If you look at the picture, you can understand that this tool does not resemble a shovel in any way. It also has other differences from a regular bayonet shovel. So, the model’s handle is much higher and should be at shoulder level. Some models have a crossbar at the top, which allows for two-handed operation.

The main advantages of the miracle shovel include the fact that it can perform several functions:

- Loosens the soil;

- Breaks up large clods of earth;

- Pulls out the roots of any weeds without leaving them in the ground;

- Easily digs potatoes, beets and other root vegetables.

The operating principle of this device is not complicated. If we describe it in general outline, then it will look like this: ordinary forks mounted on the back stop loosen the ground using the force that a person transmits manually tool, pressing on the handle.

At this time, the second fork teeth, located opposite and entering the lock, break up large lumps of soil during the loosening process. As a result, the earth is well dug up and loosened.

The ripper is equipped with a front stop, which provides good stability to the entire mechanism. Looking at the work of a miracle shovel, it can be compared to scissors that cut and crush piles of earth. At the same time, there is no need to cultivate the land with a garden rake.

The miracle shovel is an indispensable assistant for gardeners and gardeners. It is especially good to use it when digging large areas, since with the help of this tool the work process can be accelerated several times.

With proper use of this device, you can independently dig up about 20 acres of land. And if you use several of these shovels, you can efficiently cultivate a whole hectare of land.

Watch the video! Miracle shovel, which one to choose

Types of universal rippers

Today there are a large number of miracle shovels on sale that represent various designs. Some types of products can change the depth of soil digging, others are equipped additional functions. In addition, along with a manufactured product, on the shelves you can also see devices made by yourself according to special drawings.

Among industrial devices, there are several most popular models.

- Classic miracle shovel. Often made by gardeners themselves. This device, consisting of the main forks and a back stop, significantly reduces the load on the body. This increases the speed of work. The disadvantage of this design is that it does not break up earth lumps, so you have to additionally use a rake. Also, the tool can only be used for digging up black soils that are processed regularly;

- Plowman. For better labor productivity, manufacturers are constantly trying to improve the design. Thus, many rippers were created, including the Plowman. A special feature of this device is the length of the bayonet, which can reach 15 cm. Thus, the shovel ensures loosening of any type of soil;

- Mole Available with a fork length of about 25 centimeters. It was created specifically to allow deeper digging. In this case, the plants should be planted immediately after cultivating the soil. It is worth noting that digging soil with such a unit is not easy. Compacted earth or alumina are especially difficult to work with;

- There are universal miracle shovels. With their help, you can dig soil up to 20 centimeters deep, but only if the soil is black soil and freezes only to 10 cm. Under more severe conditions, this shovel is not suitable for cultivation garden crops. But it is suitable for decorative digging.

Watch the video! Digging an area for potatoes with a miracle shovel

Making a miracle shovel with your own hands

Sometimes gardeners or gardeners cannot choose the right ripper model for certain reasons. In addition, production tools may not be affordable for everyone. Therefore, many people undertake to make a miracle shovel on their own. Moreover, such a miracle shovel, made by hand according to drawings and exact dimensions, turns out no worse than a factory one.

Drawings

To understand how to make a miracle shovel, you need to understand the drawings. After this, you should prepare the material to create a garden device. Also, to assemble the product you need to prepare in advance special tools:

- metal fittings and square pipe;

- welding machine;

- sharpening machine.

It is important that the design matches all given parameters, the main ones being depth and width. These dimensions will depend on how deeply the ground freezes in the region, as well as for what purposes it is collected. this design. So, the device can be used for digging soil or for loosening it. If the device is made only for loosening, then a depth of 10 centimeters is enough.

If a tool is created to loosen the ground in which it is necessary to immediately plant greenery, then when assembling it it is necessary to take into account that the depth of the pothole should be 5 centimeters deeper than the freezing of the ground. It is worth noting that this mark will be different in each region.

When choosing the width of the forks, you should take into account not only your wishes, but also your physical strength. It is important that the width of the forks does not exceed 50 centimeters. If it works strong man, which can dig up huge piles of earth, then you can make a miracle shovel according to individual parameters. To do this, you need to find the necessary drawings and videos on special websites on how to properly make the structure with your own hands.

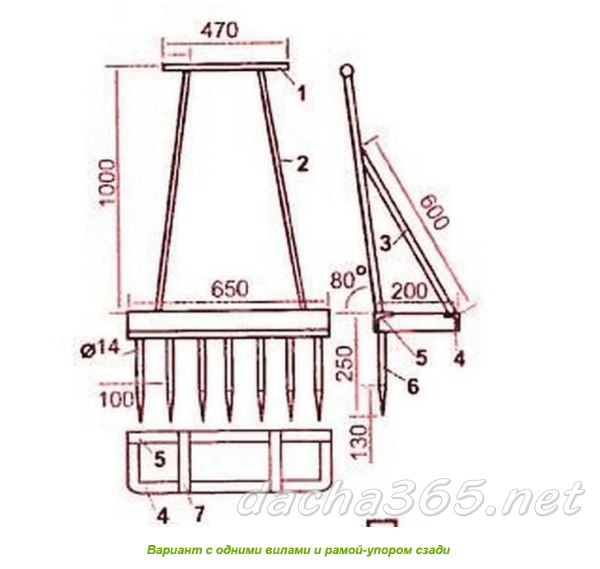

Stages of making a miracle shovel with your own hands (drawings)

- Before you begin assembling the device, you need to prepare all the parts. First, we take pre-prepared steel rods and cut them to length. We make bayonets from them, and then sharpen their ends.

- cut off the supporting strip from square pipe.

- A metal pipe will be needed to make the base of the cutting.

- A thrust strip is also made from the pipe. It needs to be given an arched shape and attached to the supporting bar. All parts of the product are assembled using welding.

You can additionally mount a ripper to it, with which you can break up large lumps of earth. The design of the ripper is the same as for the main forks. Two devices are attached to the moving mechanism. In this case, the miracle shovel will be able to dig soil in areas with a slope. In addition, it will be able to efficiently crush even small lumps of soil.

To complete the creation of an amazing device, you need to select a suitable cutting. If the product turns out to be too bulky, then the stalk can be replaced with two metal pipes, which are welded to the tool, they are connected on top by a transverse one, forming two handles, which will greatly facilitate working with such a miracle shovel.

Watch the video! Do-it-yourself miracle shovel (drawings). Testing the miracle shovel in practice

One of the most labor-intensive processes in home gardening is the annual digging of the soil to ensure aeration, weed control and fertilization. A classic shovel requires sufficient effort to operate and leads to increased tension in the muscles of the back, arms, and legs. Technical thought also helps summer residents. An example of this is the garden ripper, popularly called a miracle shovel.

This unit is based on the use of human physical strength, but thanks to a special device it uses it much more economically, which leads to less fatigue and high performance. The average width of the processing zone of the device is 40 cm, the plowing depth is about 20 cm. The operating principle is based on the counter-operation of two forks, one of which is embedded in the ground and pushes it towards the other. Loosening occurs by breaking clods of soil between the steel rods of the miracle shovel.

This assistant has a number of advantages and compares favorably with both of its predecessors - a shovel and a fork. In contrast to the first, the load on the worker is reduced several times due to the absence of the need to lift the cut-off layer and turn it over. Unlike the latter, the quality of loosening is much higher and the area processed in one pass is increased. In addition, the lack cutting edge allows you to increase the effectiveness of weed control, since the rhizomes are not cut, which prevents the proliferation of weeds.

Design and operation of the tool

The updated design of a device familiar to many is represented by several main elements. The first of them is a working body, represented by wide forks, controlled using wooden cuttings length suitable for the worker.

The main ripper is hinged to the auxiliary one, which is represented by a support frame and several teeth arranged so that the working teeth pass through them with equal clearance. To save effort on the part of the worker, there is a stop at the back of the miracle shovel, which allows you to transfer part of the load directly to the cultivated soil.

When working, it is recommended to move backwards, as with standard digging of earth. The support platform with auxiliary forks is installed on the ground. It is better to additionally fix the back stop with your foot to avoid horizontal displacement of the entire device. The working forks are inserted into the soil at an angle of about 60-70 degrees, and pressure is applied to the working handle (handle).

As a result of the actions described above, the part of the soil limited by the teeth begins to move upward. When encountering additional teeth of the auxiliary forks, additional crushing of the soil and its retention occurs. This contributes to the absence of soil mixing and its high-quality loosening.

Making a miracle shovel with your own hands

The miracle shovels described above are already on sale in country stores. The cost of the device starts from 1000 rubles, which limits the demand for them among the average buyer. At the same time, having a minimum list of equipment and materials, it is not difficult to make it yourself.

To work you will need:

- round or profiled steel pipe with a cross-section (diameter) of 20-25 mm;

- rod round section with a diameter of 8-10 mm. (you can use reinforcement) about 2 m.p.;

- piece steel pipe diameter 40 mm, length 200 mm;

- steel sheet 2 mm thick, size 20x20 cm;

- grinder with a metal disc;

- drill with a set of drills;

- welding machine.

Let's start manufacturing with the support frame. It is convenient to make it from a round or profile steel pipe with a cross-section of at least 20x20 mm.

Bend or weld from separate parts A-shape frame size in plan 460x800. Attach the cross member with a weld seam. Drill holes with a diameter of 8 mm in it every 5 cm at an angle of 20 degrees to the plane of the support. Install cut steel rods, each 200 mm long, into the holes and secure with a weld. At the top of the support, weld a T-shaped stop, located at an angle of 120 degrees to the frame.

There is another option for making a support platform for a miracle shovel. In it, the foot rest is located in the same plane as the support, and the auxiliary teeth have a small distance from the ground, provided by the bend of the front part of the frame.

Which option to choose for the device depends only on you. Next, we will make working forks from a piece of steel pipe and several rods, connecting them using welding. It is better to make the teeth not straight, but slightly bent in the front part. They can be welded into drilled holes or attach to one of the faces steel profile, having previously lightly sharpened the working parts using sandpaper. To attach the handle to the side of the pipe opposite to the teeth, weld a piece of pipe with a diameter of 40 mm, previously flattened on one side.

Triangular ears with holes attached to the working forks will help provide a hinge connection.

The same ears should be welded to the support frame, distributing them opposite the stop.

The distance and location of both pairs of fasteners must ensure the functionality of the device and an equal distance between the teeth. As a working axis, you can use a M10 threaded stud or a similar bolt with a washer and a nut.

For home craftsmen who have an engineering education or have not forgotten their school drawing course, we offer a set of drawings for making a miracle shovel with your own hands with the specified dimensions.

To better read the drawings, you can enlarge them.

Using our instructions, every gardener can easily make such a device and will be able to use it in the spring when cultivating their plot.

Dear readers, if you have any questions, please ask them using the form below. We will be glad to communicate with you;)

Digging up a plot of several acres is not an easy task; buying a walk-behind tractor is justified if you have a plot of land of at least half a hectare, and DIY miracle shovel made of metal or plastic, for many it becomes the best solution.

What kind of miracle shovel is this, the drawing of which is so popular?

It has long been known that loosening the soil has a much more beneficial effect on its condition than digging it up. In addition, working with a spade requires a lot of endurance, and often takes a lot of strength and time. Each movement when cultivating the land is associated with a load - stick the surface of the shovel bayonet into the ground, press your foot on a special step, press the handle like a lever, lift a large lump of earth and throw it to the side. Have you forgotten anything from the sequence of stages of a simple technique? Even if something is missed, the essence is conveyed correctly. However, for work with hard soil, special digging forks made of hardened steel have long been used. It is this gardening tool that has become part of the miracle shovel today.

It is not known for certain who invented this tool; it is believed that it was first developed in Yekaterinburg, but it is quite difficult to verify the accuracy of the information. Therefore, let’s just look at the design of industrially produced devices. As already mentioned, the idea was based on pitchforks, but not the usual two- or three-pronged ones, but much wider ones, from 35 centimeters. With a pitch between the working rods of about 5 centimeters, this amounts to as many as 7 teeth, the length of which is a quarter of a meter. But, of course, this is not the whole miracle shovel; the drawing is usually represented by a diagram that is more complex than just a pitchfork.

Main ripper components

Let's go in order. In most models, the forks are movably mounted on a horizontally oriented frame extended forward with cross stop in the rear (sometimes the frame is replaced by a slightly curved slide). Between the teeth there are counter-directed rods, somewhat shorter, a kind of analogue of a rake. A tool may have two handles, but most often it is an ordinary handle, like a shovel or the same fork. At the same time, it is not always convenient to use a wooden handle, since such a lever can break if the teeth catch on roots. As a handle, you can use a metal pipe, for example, made of aluminum.

If the wooden handle breaks in the socket gardening tools at the base, it is quite difficult to remove the fragment, and it is best to try to drill it out with a drill.

Simplified models are also available. They consist only of a frame, which is also a stop, since it is located behind the working part. The teeth are fixed directly to the front rod, at the ends of which there are fasteners for two handles. Exactly this type Miracle shovels are most often made in home workshops in suburban areas by zealous owners. The material can be a regular pipe with a diameter of 20 centimeters, metal or plastic. The latter option is somewhat less durable, but easier to manufacture.

Let's find out how the miracle shovel works, without video

Above we described the process of working with a conventional spade; now it’s time to shed light on how exactly the ripper in question should be handled. So, the standard factory version with a frame is installed on the ground at the edge of the area that needs to be processed. Lightly lift the tool by the handle and point the forks into the ground. Next, press the frame with your foot (an action that does not require special effort). The teeth easily penetrate the entire length of the soil; now all that remains is to press the handles so that the rods of the working part cut through the soil, loosening it and lifting individual layers. This is where counter teeth are needed. The purpose of this part is to break up clods of earth raised with a fork.

Understand how the miracle shovel works own production, you can do it without video, because everything is simpler here. Firstly, due to the closer arrangement of the teeth on the frame, the working part does not lift large lumps of soil, breaking them during movement. Secondly, in factory models, the hinge of the moving part sometimes gets clogged with earth, which makes it difficult to turn, and the wooden handles that are inserted into special sockets often break. In a homemade device, the parts are rigidly connected, and therefore breakage and jamming are excluded. There is a possibility of deformation of welding or soldering seams, as well as breakage plastic parts if there are any, but this can only happen after a significant service life of the tool.

Instructions on how to make a miracle shovel with your own hands

At home, it is better to make a simplified model, which differs from the factory one in the complete absence of moving parts. If you have a welding machine, it is best, of course, to make metal equipment, otherwise optimal solution there will be a design from plastic pipes. It is not advisable to assemble the ripper on bolts, since during operation such connections will become loose and the nuts will have to be tightened all the time. Regardless of whether the device is made of plastic pipes or metal ones, you will still have to weld them, so we’ll just look at the process step by step of how to make a miracle shovel with your own hands, without focusing on the tools.

How to make a miracle shovel with your own hands - step-by-step diagram

Step 1: Preparing the Parts

We will need two pieces of metal pipe of 60 centimeters each and the same number of 25 centimeters each. We will also need a pair of corners (namely triangular plates) and 6, 7 or 8 teeth from the forks, or simply rods made of high-carbon steel. If you intend to make a frame from plastic, then in addition to the pipes you need 2 angles and 8 or 9 tees, depending on whether the ripper has six or seven teeth. Also, for PVC variations, adapters for connecting to metal pipes may be needed. In any case, it is advisable to make the handles steel, adjusting them according to your height.

Step 2: Frame Assembly

It will not be difficult to assemble the desired blank of the future design from metal; it is enough to make 4 seams welding machine. It’s another matter if you don’t know how to work with this unit and have never picked up a holder with an electrode. Then most affordable option– PVC, fortunately, the blanks listed above are not difficult to obtain. First, using 4 corners of pipe sections of the above length and two tees, we assemble the rear part of the frame. To do this, we weld equally oriented corners on the sides to a sixty-centimeter piece of round profile, from which the sidewalls extend 25 centimeters. Next, we fix the tees on them with the forks up, and then, using short pieces, 2 more corners, with which we close the contour of the frame. Now the front part. We also weld tees to the last corners with small pieces of pipe and continue this until we connect them all. The side outlets of the tees should face down.

Step 3: Fixing the teeth

We weld the rods onto the metal frame so that they bend forward, this will make it easier to move the working part in the ground. On a plastic one we position it in exactly the same way, however, if the teeth turn out to be thinner than 13 millimeters at the base, you will have to not only fuse them, but also fill the void in the tees epoxy glue or automotive putty based on it. But it’s best, of course, to weld thin rods onto thicker bases and fuse them into PVC.

Step 4: Attaching the Handles

We weld the handle to the metal frame in the front part at the corners, additionally fixing it with triangular plates (in the end you get 3 connections, two end and one with a circular seam). TO plastic construction It is also better to attach steel handles, but only after cutting threads at their lower ends. We weld adapters from plastic to metal to the tees, the side outlets of which look upward, using short pieces, and screw a pipe with a diameter of 20 centimeters into them. The miracle shovel is ready to go.