On the eve of the next summer period I was puzzled by the issue of increasing the comfort of being in nature, namely, making something to land on. On the Internet, the idea of chairs made of propylene pipes was spotted.

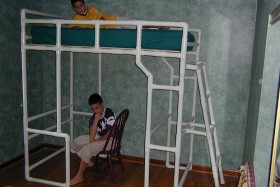

The first prototype was a high chair for a child.

Materials used:

- polypropylene 20mm pipe 2m,

- corners 20mm 90 degrees 8 pcs.,

- furniture bolt 50x6 2 pcs.,

- nuts with nylon ring 2 pcs.,

- jeans trouser leg 1 piece,

- a little rope.

Manufacturing process (briefly).

It is not difficult to determine the size of the chair; I took approximately the dimensions from baby chair with some modification. It is necessary to calculate two rectangles of the same height and the difference in width by the diameter of the pipe used.

Pipe cutting - no comment.

Welding polypropylene pipe. There is nothing complicated here (for those who have dealt with a soldering iron and polypropylene pipes), one nuance - the dimensions of the rectangles are small, the structure is closed and rigid (it is impossible to solder the last joint without helpers). I got out of the situation in the following way: I soldered two halves of the rectangle (two joints remain to be soldered) and on one half I “drove” the pipe through a soldering iron (I only heated the pipe as for welding, but without connecting it to the corner of the second half). After “running” and cooling the pipe, it hardly fits into the corner and stays in it quite tightly. And then we heat the pipe and the corner of the opposite joint for joints and deftly connect two joints at once (one is welded, and the second is simply joined to the “driven” pipe). This method is not final, it was more convenient for me, and constructively this was quite enough.

After welding the frame, it is necessary to drill holes for the screws (no comments).

As a seat, I used material from a jeans leg, sewn in two layers.

To give rigidity to the chair, you need to tie the lower parts with a rope (you can see it in the photo), otherwise the chair will move apart.

The resulting chair can withstand an individual weighing 90 kg (checked personally) and can easily be used by an adult.

After the successful implementation of the project for the child, it was decided to make a high chair large sizes for comfortable use by an adult (namely for the father, i.e. the author). In terms of materials, changes were made only through a 25mm pipe 3m long, respectively, the corners for 25mm in the same quantity, and 6 by 6 furniture bolts in the same quantity. Manufacturing process using the technology described above.

In conclusion, I would like to note:

- a simple pipe was used (without fiberglass and anything else), when buying a pipe, try the rigidity (for bending, the stiffer the better);

- the seat can be made from any available material (fabric, tape, rope);

In general, the chairs turned out to be light, durable, comfortable, compact for transportation and with a pleasant appearance.

Good luck everyone!

Pipe welding completed

Finished product No. 1 (temporary bolts).

Product No. 1 and No. 2 (temporary bolts)

The final option.

P.S. Today both chairs were subjected to a barbaric test of 102 kg of live weight, the result was positive. Accordingly, this process was filmed on a mobile photo.

Plastic, which has entered our lives, is gradually displacing the usual wood and iron from everyday life. We are not talking about plastic bags and utensils, but about the familiar polyvinyl chloride pipes, which are gradually replacing rusted cast iron water and sewer pipes in our apartments.

Or rather, first of all, about the remains of these pipes, which lie like dead weight after repair or construction and sometimes significantly interfere with the owners. Few people think that this is an excellent material for bringing creative ideas to life.

To begin with, these seemingly unnecessary scraps can be used to make excellent organizers for storing all kinds of household items.

If you select samples of the same diameter from the available scraps, then having previously cut their ends at one angle, you can fasten them in the right place and use them to store pencils, brushes, scissors, small tools and other things, for example, for shoes, yarn or wine.

Instructions on how to make such a pencil stand can be found here.

If you have developed creative imagination, then with the slightest production skills you can turn waste into chic flower vases, original frames for a mirror or lamp.

You can also make such cute flower vases.

Clear out the piles of waste pipes and make something worthwhile out of these products, even if you have to buy a few more. After all, the price of these materials is low, and thanks to the high mechanical strength, excellent wear resistance, rigidity and corrosion resistance of PVC pipes, everything you make from them will be practical and durable.

Let's look at several groups of products for which plastic pipes are ideally suited.

Young families sometimes find it difficult to immediately find a large sum for equipping a children's room, and therefore the option of making children's furniture from improvised materials will be relevant for them. Using plastic pipes and fastenings for them at the desired angle, it is easy to assemble bunk bed or a mini office for a teenager with a bed on top.

Using the same principle, a frame for a toy house is mounted in a children's room or in a country play area.

If such furniture is too simple for a city apartment, then for country house she will be in place. From plastic pipes summer chairs for both children and adults, tables, gazebos for outdoor recreation are easily made.

If you have space on your property that allows you to organize a small football field, then the goal for the game can be easily constructed from such pipes. You can dry your children's clothes on such a wonderful hanger.

Children can also make such a wonderful sword or an outdoor shower :)

Another idea will be interesting for owners suburban areas. Growing seedlings is a kind of ritual for gardeners. And therefore, the question of how to arrange this particular period of the gardening season worries many. The pipes are useful for making mounts for lighting, for shelves for boxes with seedlings and for directly growing crops.

![]()

How interesting is the option of using such pipes to design a trailer cart for a bicycle? This is already a whole vehicle unit for moving goods. And the bicycles themselves will find their perfect place in a convenient parking lot made of pipes, which will immediately attract new fellow cyclists to you.

The tips given do not cover the entire huge number of possible crafts made from plastic pipes. We only looked into a small gap of creative ideas of folk craftsmen, but how many more were made by restless home craftsmen. Therefore, if you decide that this material does not contradict your environmental needs, you can safely start making whatever your imagination tells you.

Not very long ago, PVC materials appeared on the market in our country, which are intended for the installation of plumbing equipment. But our craftsmen were able to come up with a completely different use for them - they are used to make various things for the home and garden. Today we will tell you how to make a chair from PVC pipes.

It is fashionable to make chairs from PVC pipes different types, both for children and adults. The only difference is the increase in size in preparation for assembling a chair for an adult. These chairs are very easy to assemble; you don't need any special knowledge.

The only thing you need is the simplest tool and a little imagination.

What to prepare first:

PVC pipe – 3 meters;

Elbow 90 – 8 pieces;

T-shaped connections – 6 pieces;

Adhesive for PVC products;

Metal file;

The material from which the chair seat will be made.

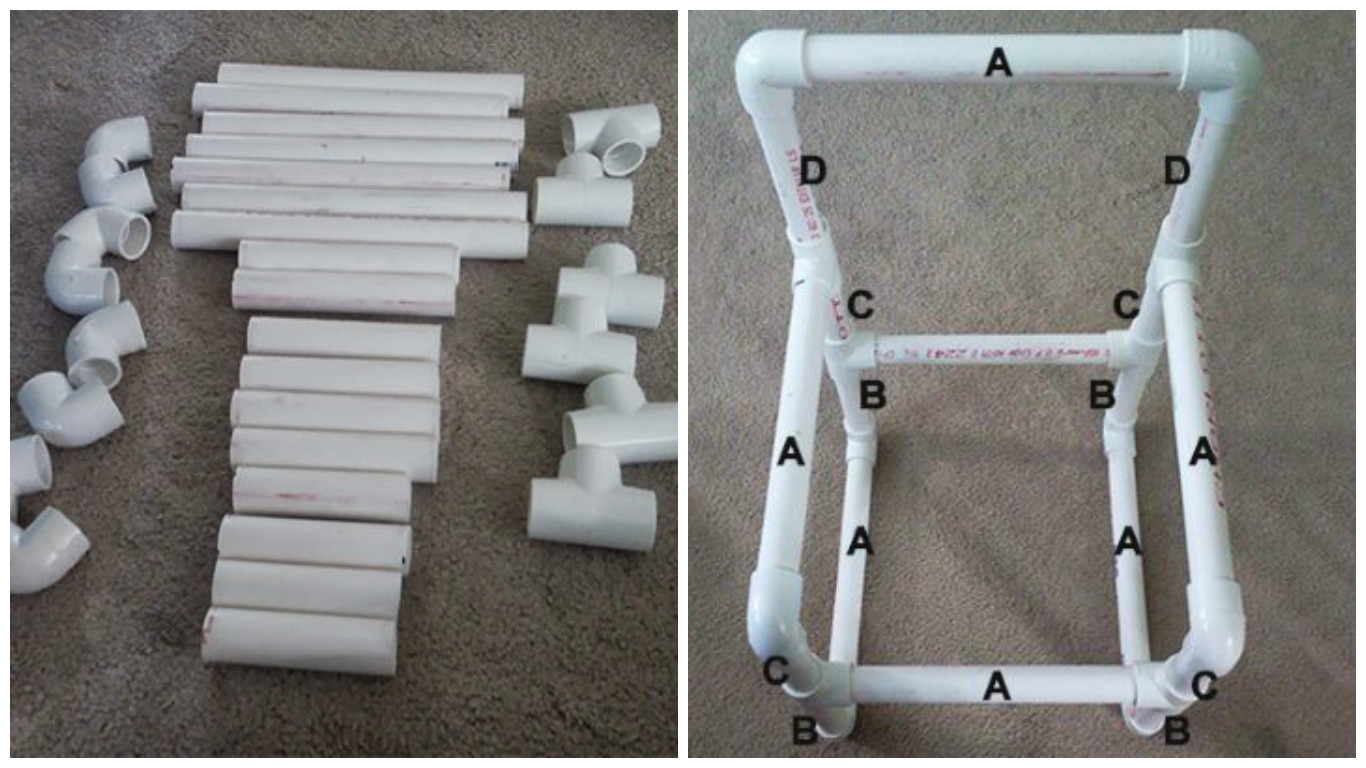

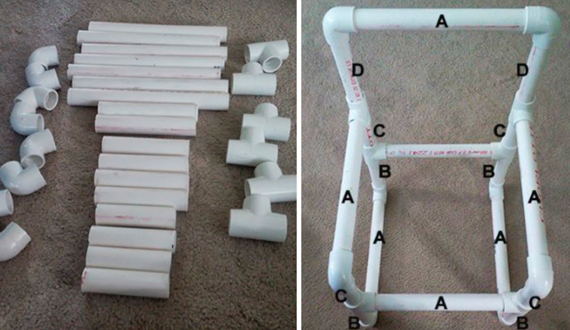

For small chair for a child up to two years old we will need:

A – length 25 cm. – 7 pcs.

B – length 13 cm. – 4 pcs.

C – length 10 cm. – 4 pcs.

D – length 15 cm. – 2 pcs.

Chair for a child aged 4 years:

A – length 33 cm. – 7 pcs.

B – length 20 cm. – 4 pcs.

C – length 13 cm. – 4 pcs.

D – length 18 cm. – 2 pcs.

Chair for a seven year old child:

A – length 41 cm. – 7 pcs.

B – length 25.5 cm. – 4 pcs.

C – length 13 cm. – 4 pcs.

D – length 23cm. – 2 pcs.

The parts under the letter "A" determine the width and depth of the seat.

The length of the pipes “B” determines the height of the seat from the ground.

Details under the number “C” are the height of the armrests, and under the number “D” the height of the backrest.

All tubes under the letter:

A - means the depth and width of the seat.

B is the distance of the seat from the surface.

C – this is the height of the armrests.

D – Determines the height of the backrest.

DIY chair made from PVC pipes

For big man We calculate the height and depth individually, but approximately these can be the following indicators: seat height - 45 cm, depth 47-53 cm, width 50-55 cm.

All parts must be sawed with a hacksaw specified sizes. If you are assembling a chair for the first time, then you should not use quick-drying glue, since you will need to work very quickly and not make any mistakes - redoing it later will not work.

Assembly should begin from the back, and as assembly progresses, add the necessary parts to it.

Tip: to make it clear how to assemble a chair, assemble it without using glue, like a construction set. Then carefully disassemble, placing all the parts in the required sequence, and after that start gluing the parts.

It is important to prepare the fabric for the seat right away, since it is stretched during the assembly process. Otherwise, we do not glue the front transverse pipe of the seat and the upper transverse pipe, leaving the opportunity to disassemble and tension the material.

For the seat, you need to take a dense material, first sew a strip to the size of a chaise lounge. There should be special borders sewn along the edges into which the pipes of the seat and back will need to be threaded.

Although there is another option, in order for the material to be easily removed and washed, you can fasten it with buttons or with a zipper. Although you can come up with your own design for the seat and back of the chair, you can, for example, completely cover it and get a small chair. Of course, this will take a lot more time, but the result will please both you and your child.

Modern industrial technologies make it possible to make unique objects even from such seemingly ordinary objects as chairs. And what is important, their assembly can be done with your own hands. Connection creative imagination will help you create chairs not only from metal ( profile pipe), but also from plastic pipes. Just think, products made of polyvinyl chloride, originally intended only for the installation of water supply and sewerage, have become a real godsend for home craftsmen. After all, despite their simplicity, they are easily and quickly transformed into the most necessary, and sometimes unexpected, household items.

Choosing the right material

All pipes made from polymers are commonly called plastic. However, their appearance and the properties differ markedly due to the difference in the raw materials. Accordingly, the methods of connecting them differ.

Polyvinyl chloride (PVC) pipes:

- Various colors (originally white).

- They are connected to the fittings with glue; you can do without it (then the structure will be collapsible).

Polypropylene (PP) pipes:

- Various colors (initially black).

- Rigid, produced in the form of segments of a certain length; are connected by low-temperature welding or using metal components.

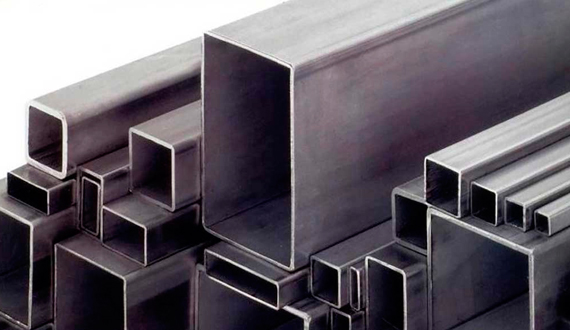

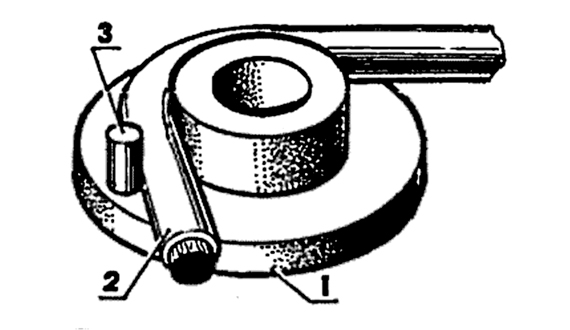

A profile pipe is a metal pipe that has a different round section. The most common are square and rectangular, but oval and diamond-shaped ones are also produced. It is easy to achieve the required bend from a profile pipe using a “Snail” type machine.

Shaping PVC tube

To make it easy to bend or flatten a PVC pipe, it should be heated with a gas burner, then quickly given the required shape. As an exception, in the absence of a burner, it is permissible to heat an element of the future product over a fire gas stove. Cutting pipes can be done with a metal saw or jigsaw; the parts can be fastened using a convenient method cold welding(a special adhesive composition is required for this purpose).

From pipe elements you can make beautiful garden chairs with your own hands, the smooth lines of which can be envied. As already noted, this result is achieved by heating at gas burner followed by hand shaping the element the desired shape. You just need to remember to let the PVC pipe cool after processing.

For a beginner home handyman It is not necessary to immediately try to make a designer chair from the proposed material. Even an ordinary product with strict side geometry will look great. It’s easy to make a seat for a chair with your own hands from ordinary fabric, chintz or cotton. Having mastered these simple skills, you can begin to assemble more complex products from PVC pipes, for example, folding chairs.

Assembling a simple plastic chair

Before you begin, you need to decide on the dimensions of the product. They can be arbitrary, but undoubtedly must correspond to the functional purpose of the chair. The easiest way is to take dimensions from any existing sample. Then, according to the selected parameters from polypropylene pipes(or PVC) can be cut into blanks.

What materials will be needed for the work:

- pieces of plastic pipes;

- 1 crosspiece;

- 4 turns 90°;

- 8 tees;

- 4 plugs;

- thick dense plywood (for the seat);

- a piece of foam rubber;

- a piece of fabric to cover the seat.

What tools are useful for making plastic chairs:

- drill;

- stapler with staples;

- pipe cutters (or hacksaw);

- special soldering iron for heating plastic tubes.

We begin to assemble the chair from the seat, solder pieces of PVC (or polypropylene) pipes of the required size to the crosspiece. Then we drill holes in the pipes for future mounting of the seat.

We attach tees at the ends of the fixed sections. We solder the prepared blanks on both sides of the tees. One blank will serve as a leg, the second will support the armrest. The height of the armrests is determined independently, based on convenience. To assemble the armrests you will need pieces of PVC (or polypropylene) pipes, a tee, and a 90° rotation. We solder the finished handles to the seat blank.

Installation features

Curved tubes will add individuality to the backrest, but even their absence will not prevent you from making a good chair from straight polypropylene pieces. The back is made from 2 blanks, which can be conveniently assembled either separately or gradually attached to the product being assembled.

The chair is almost ready, all that remains is to nail the seat. As its base, you can use 10 mm thick plywood. According to its size, take a piece of foam rubber (you can take a piece of a blanket). Any fabric with a sufficient margin of strength will be useful as a covering.

Foam rubber laid on plywood is covered with fabric and attached using a stapler (an alternative is a hammer and ordinary nails). After which the seat is screwed on with self-tapping screws (the holes were prepared earlier).

After checking the height of the legs, plugs are put on them. The finished chair can be painted (before attaching the seat), although plastic is available different colors, And the best solution will select the required one in advance. Assembly time is up to 3 hours.

The presented design is quite simple; anyone can complicate it and make it more reliable. To make a chair with your own hands, you can take pieces of a larger diameter; the legs can be additionally strengthened with the same cross that is installed under the seat.

Plastic products are durable, there is no need for painting or treatment with protective compounds. Having such furniture in the garden or yard, you don’t have to worry that it will get wet and rot. But the most important thing is that it is easy to make with your own hands.

Making a metal chair

Metal furniture is easy to make by connecting straight sections of pipes and using the bending method tubular elements on a “Snail” type machine. The order of operations is as follows:

- The tube is plugged at one end.

- The workpiece is filled with fine sand.

- Plug the other end.

- Place the piece in the machine, securing it between the pin and the protrusion on the disk.

- By applying force, bend a section of the profile pipe to the required angle.

- To apply less effort, you can heat the bend with a blowtorch until it turns red.

- To get the bend as it should, you will need to use plaz (cardboard or plywood with the outline of the part applied).

- The elements can be connected by welding or threaded connection. For fastening, it is permissible to use wooden bushings into which self-tapping screws are screwed.

- After welding work The resulting seam is cleaned with a file or a grinder so that the joint becomes smooth.

To make a simple chair from a profile tube (20x20 or 20x40), you will need:

- welding machine with electrodes No. 3;

- corner grinding machine(Bulgarian);

- file, sandpaper;

- measuring instrument;

- drill with attachment.

The dimensions of the frame are selected based on personal preferences. The seat can be made from boards, plywood or furniture board. If you want to get an all-metal chair, you should cut the required number of tubular elements for the seat and attach them to the frame by welding or bolts.

PVC pipes received widespread in plumbing due to its excellent performance properties. But craftsmen These products found a lot of applications in other areas, for example, they began to use professional pipes for making furniture with their own hands. You can assemble a chair, table or even a bed from this material; this does not require special knowledge or experience in the field of furniture assembly.

Material advantages

Plastic pipes have many advantages over other materials for making furniture and interior items. For example:

- Affordable price. Polypropylene pipes have an affordable price. And some craftsmen make crafts from materials left over after installing communication systems at home.

- High strength. The walls of plastic pipes are thick enough to withstand the water pressure in water supply systems, so PVC structures can support the weight of an adult. They also demonstrate resistance to other types of mechanical stress.

- Nice appearance. PVC pipes are different correct forms, pleasant white color. This has a positive effect on the appearance of the finished chair; such structures do not need to be painted.

- Light weight. Due to their light weight, products made from polypropylene pipes can be easily moved from place to place and taken with you to the dacha.

- Safety. PVC products do not have toxic emissions, so they can be used to assemble furniture even for small children.

- Corrosion resistance. Furniture made from polypropylene pipes can be used not only at home, but also outdoors, since products made from this material are not afraid of precipitation and high humidity, because plastic does not corrode.

- Easy to install. Assembling a plastic pipeline with your own hands is not difficult and is done very quickly. Structural elements can be connected without soldering. In addition, such furniture is easy not only to assemble, but also to disassemble if necessary.

- Long term of use. A chair made by yourself from PVC can last up to 50 years.

To make a structure from plastic pipes, the craftsman will need a minimum set of tools, including a marker, tape measure, and a hacksaw. Sometimes glue and screws are required, although you can often do without them.

Assembling a chair with a soft seat

You can make your own chair from leftover plastic pipes. The dimensions of the product are arbitrary; for example, you can take measurements from a regular chair. The assembly work includes the following steps:

- Marking. Markings are applied to the pipes in accordance with the measured parameters. After this, the material must be cut into fragments.

- Seat assembly. To form the base of the seat, a cross is used, to which 4 short pieces of pipe are soldered; they will go from the cross to the legs. It is important that the joints are secure enough, because this part of the chair must support the weight of a person. Soldering is carried out as follows: you need to place the soldering iron on a level place, screw on the drone, as well as a sleeve of suitable dimensions, set the thermostat to 260 degrees, and then plug the tool into a power outlet and switch the toggle switch to working position. When the nozzles warm up, you need to install the edge of the pipe and the coupling in them, wait a few seconds. After this, you should remove the products and join the elements at right angles. Then you need to wait for it to harden. If the master does not have a soldering tool, then for assembly you can use glue, another possible option– fastening parts using self-tapping screws. However, it should be remembered that self-tapping screws can ruin the appearance of the product.

- Installation of legs. You need to weld a tee to the free edges of the plastic pipes, and then insert the legs into the lower holes of the tees yourself. The lower ends of the legs are closed with plugs. You can also make a rocking chair, to make it you need to take PVC pipes large diameter, bend with blowtorch, attach to the legs from below (instead of plugs).

- Assembling handrails. To each pipe that will be used as a handrail, you need to attach an elbow fitting on one side and a tee on the other side. Then a short piece of PVC pipe should be connected to the fittings. After this, the handrails are attached to the seat (inserted into the tees connecting the legs to the seat). In this case, the tees of the handrails should be on the back side, where the back of the chair will be attached.

- Back assembly. To the ends of the PVC tube, which is intended for the back, you need to weld a fitting-turn approximately half the length of the back. Tees are soldered to the edges of these sections, which are connected to each other by another tube that acts as a stiffener. If necessary, you can make several such ribs. Then two more pieces of pipe half the length of the backrest connect the backrest to the railing crosses.

- Seat installation. At the last stage of making a stylish chair with your own hands, you need to cut the seat out of a piece of plywood, screw it to the cross using self-tapping screws, and then cover it with foam rubber and cover it with fabric.

At this point, the work of assembling the chair from plastic pipes is completed, the furniture is ready for use.

Making a children's chair

From PVC pipes you can make a chair with your own hands not only for an adult, but also for a child. The master will need tools and a little imagination. Before starting work you need to purchase:

- about 3 meters of pipe;

- 8 elbow fittings 90;

- 6 T-connections;

- glue for plastic;

- hacksaw for metal;

- the fabric from which the seat will be made.

Below are the parameters of the elements of the future design. Each list item contains 3 numbers: the first is for a child under 2 years old, the second is for a child under 4 years old, the third is for a child 7 years old:

- Seat depth and width: 25, 33, 41 cm. 7 pieces of plastic pipes.

- Height from the bottom of the product to the seat: 13, 20, 25.5 cm. 4 pieces.

- Armrest height: 10, 13, 13 cm. 4 pieces.

- Back height: 15, 18, 23 cm. 2 pieces.

Assembling the structure with your own hands begins with the back, then other parts are added to it. If the work is performed by a novice craftsman, then you should first assemble the product without glue, and only when it becomes clear that all the parts are made correctly, you can assemble the structure using glue.

You need to prepare a thick, strong fabric for the seat in advance. You should sew a strip out of it like in a chaise lounge. The fabric will be stretched directly during the assembly process. Alternative option– leave the front transverse seat pipe and the upper transverse pipe unglued, so that later you can disassemble this part of the structure and tension the material. To make the seat easy to remove for washing, you can fasten it with a zipper or buttons.

Installation of creative furniture

If after the renovation there are a large number of scraps of plastic pipes left, then you can make a luxurious creative chair out of them with your own hands.