Before talking about the technical details and intricacies of internal cladding with OSB or OSB boards (aka OSB, OSB sheets), it is worth thinking about the feasibility of this event. Installation of OSB boards indoors takes place in two cases, namely:

- If you have frame house and the frame is not sheathed yet.

- If the pattern and texture of OSB boards are a decorative element.

If you just need to level the walls, then for this purpose would be better suited plasterboard, since it is cheaper and more convenient to work with during installation and further finishing.

Technologies for external cladding of a house are described in the article:. Let's look at the question here correct installation OSB boards on the walls inside the house.

Selecting slabs for installing OSB on walls inside the house

When using any material inside a house, including OSB boards, you should pay attention to its harmlessness to the health of the inhabitants of this house. 34 years have passed since the appearance of OSB boards, and all these years the debate about the environmental friendliness of OSB boards has not stopped. In fact, there are grounds for these disputes, since in fact, when gluing wood chips, polymer resins containing formaldehyde are used. But formaldehyde is also found in many other surrounding things, for example, in fabrics in laminated chipboard furniture, combustion products, etc.

OSB boards on the walls inside the house.

To prevent people from being poisoned by formaldehyde, enlightened Europeans established control over the production of OSB boards and divided the harmfulness of boards into classes. Boards with formaldehyde emission class E1 are harmless to human health and are used in the construction of residential buildings. Therefore, when purchasing OSB panels, choose a reliable and trusted manufacturer, as your health may depend on it. The Austrian four-star hotel Arlmont, whose interior decoration is replete with OSB panels, can say better than any words about the environmental friendliness of OSB panels.

Hotel Arlmont, OSB sheets are used in the interior decoration.

Hotel Arlmont, OSB sheets are used in the interior decoration. OSB boards are divided into water resistance classes:

OSB-1 is the board class most susceptible to moisture and has the lowest strength. Such boards are used for furniture production.

OSB-2 is a class of boards with the same moisture resistance as OSB-1, but more durable. Such boards can be used for wall cladding in dry rooms.

OSB-3 is a moisture-resistant board with high strength. They are suitable for installation in damp areas. But with prolonged contact with water they become deformed.

OSB-4 - boards with maximum moisture resistance. They are able to withstand prolonged contact with water.

OSB4 boards are not widely popular due to their price, which is on average twice as high as OSB3 boards. Therefore, OSB3 boards are widely used. If they are treated with a primer or painted, then such slabs become resistant to prolonged contact with water.

More details about various characteristics OSB sheets can be found in the article:.

Cladding the walls of a frame house from the inside

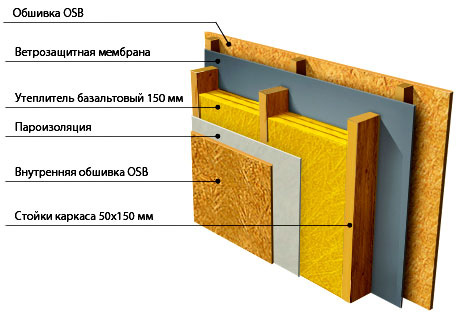

Before you begin the interior lining frame house, it is necessary to insulate the walls, cover the frame from the outside and the insulation with a vapor barrier.

It is recommended to insulate walls with mineral wool, and it is better to use slab wool, since it is easier to work with than polystyrene foam, it holds better in vertical structures and does not settle down, which happens with fiberglass insulation. Other insulation materials are not excluded and are also suitable for insulating the walls of a frame house. You can learn more about various insulation materials in the article:.

After insulating the walls, they must be covered with a vapor barrier. Vapor barrier membrane protects the wall from moisture penetration, which will keep the house frame and insulation dry. The vapor barrier is attached using the usual construction stapler, with an overlap of 10-15 cm and glued together with special double-sided tape.

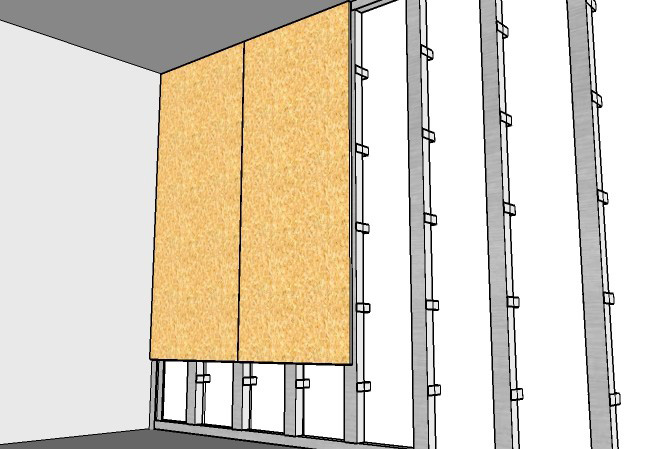

An example of a frame house wall design. WITH inside A vapor barrier film is laid on the frame, and OSB boards are attached on top of it.

An example of a frame house wall design. WITH inside A vapor barrier film is laid on the frame, and OSB boards are attached on top of it. The sheathing itself is done as follows: the sheets are screwed one after another to the frame of the house. The gap between the sheets is 3 mm. The sheets are screwed with wood screws 35-40 mm long. All holes (for windows, doors, mounting holes) are cut with a jigsaw.

Decorative wall cladding with OSB boards and lathing

As a sheathing, it is best to use a metal profile as for gypsum board. It is easy to install and is not subject to deformation like wood. When choosing wooden bars for sheathing, it is better to use bars made from dried wood, because such bars bend and curl less when they dry out. The installation technologies in both cases are not fundamentally different, so let’s consider them using the example of sheathing made of metal profiles.

In order to sheathe internal walls with OSB boards, you need to start by installing sheathing on the walls of the room.

The lathing installation technology looks like this:

1. First you need to install the starting profile, which is mounted on the adjacent walls, floor and ceiling as in Figure 1. On the sides, the profile should stand strictly vertically and close along the perimeter with the upper and lower profile.

Figure 1. The starting profile is mounted to the adjacent wall. And it closes with the upper and lower profile.

Figure 1. The starting profile is mounted to the adjacent wall. And it closes with the upper and lower profile. 2. After installing the starting profile, you need to make markings on the wall for hanging. Since the suspensions will hold vertical racks lathing, you need to mark it in such a way that two solid OSB sheets meet in the middle of the profile, you also need to install one profile in the center of each solid OSB sheet.

Hangers are attached to the wall. The sheathing is attached to them.

Hangers are attached to the wall. The sheathing is attached to them. 3. Mount the profile. When fixing the profile on hangers, it is important to control the plane of the sheathing as a rule, so that in the future a “hole” or “belly” does not form on the wall.

Installation of OSB boards on interior wall using lathing.

Installation of OSB boards on interior wall using lathing. After installing the sheathing, screw the OSB panels onto the self-tapping screws with 3 millimeter gaps between them. The gaps allow you to avoid future deformation of the slabs due to their expansion when humidity changes. After installation, the finished walls can be varnished or tinted, based on individual preferences.

OSB (OSB) or OSB (oriented strand board) is a modern structural material that has become a serious alternative to plywood, chipboard and is widely used in construction frame houses and finishing of buildings and structures. OSB boards are used to cover interior and exterior walls, floors and roofs. Wall cladding with OSB boards takes place in frame construction, when the board acts as a structural material and serves to strengthen the walls of a building, or when it acts as a facade material for concrete, brick or wooden houses, which is caused by the low price and high strength and durability of the material. In this article we will look at the question: how to attach OSB boards to the wall from the outside.

When installing OSB boards to external walls, sheathing is used for the following purposes:

- leveling the wall plane;

- creating a ventilation gap for insulation under the OSB board;

- preventing slab deformation caused by base movements, especially important for OSB slabs with a thickness of 9 mm or less.

Fastening OSB boards to the wall over insulation using lathing

Fastening the slab to the wall is carried out using lathing, which is made from wooden block, or metal profile. Technologies OSB installation slabs on the wall with wooden sheathing and metal profile sheathing are not fundamentally different. When choosing a block, it is advisable to choose a dry, planed block of 40-50 mm, then it will not twist or move after drying, which will have a positive effect on the evenness of the entire wall.

To attach the bar and profile to the wall, use special metal plates(suspensions). Before attaching the hangers, you need to draw on the wall vertical stripes, the distance between which should be half the width of the sheet, which subsequently will ensure the joint of the slabs right in the middle of the bar or profile and will make it possible to fix the OSB slab in the center along its entire length. After the lines are drawn, hangers are attached along them in increments of 30-40 cm.

A metal hanger is used to secure the sheathing.  Suspensions are attached along the marked lines. Hangers allow you to secure the sheathing over the insulation.

Suspensions are attached along the marked lines. Hangers allow you to secure the sheathing over the insulation.

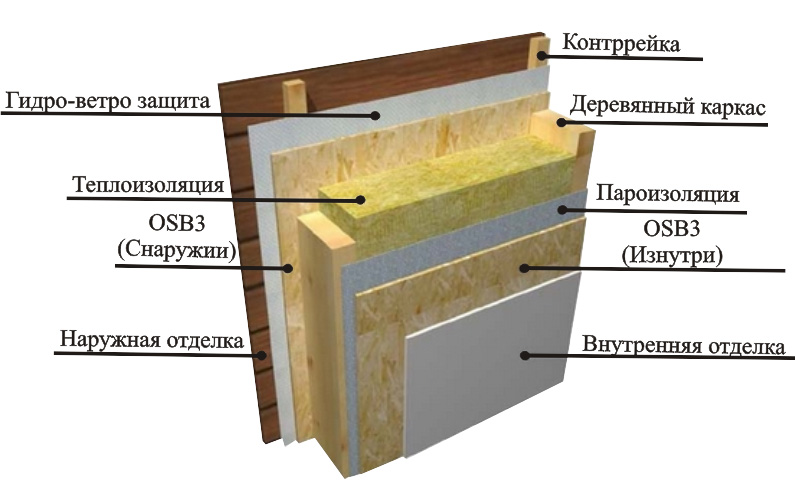

After this, the insulation is laid and covered with a membrane that protects the insulation from moisture, after which the sheathing is installed.

It should be noted that a vapor barrier is not needed on the outside of the building, as it prevents the ingress of humid air into the insulation from inside the room, and with outside structure, excess moisture should freely escape outside.

Wall with sheathing. Insulation is laid between the sheathing and the wall.

Wall with sheathing. Insulation is laid between the sheathing and the wall. After securing the sheathing, you can begin installing the OSB boards. For wall cladding, a slab with a thickness of 9 to 12 mm is most often used. If a facade is not mounted on top of the slab, then the slab must be moisture resistant. OSB slabs are attached to the wooden beam sheathing with nails at least 2.5 times longer than the thickness of the OSB sheet. For metal profile sheathing - use metal screws 10-15 mm longer than the thickness of the OSB sheet.

With this installation, the sheathing weighs above the insulation and does not create cold bridges in the insulation between the wall and the OSB boards. Thanks to this solution it is achieved maximum efficiency insulation performance. In addition, between the beams of the sheathing there is air gap, through which moisture is removed from the insulation, which also improves its performance. More detailed information about ventilated facade technology is in the article:.

Fastening OSB boards to a wooden frame

When building frame houses with wooden frame Two main approaches are used: attaching OSB sheets to the frame through the sheathing and attaching OSB sheets directly to the frame without sheathing. Let's consider the case of fastening OSB boards using sheathing.

When strong slabs are attached to the frame on the inside of the wall, ensuring good rigidity of the wall structure, then a sheathing can be made on the outside between the frame and the OSB board. The sheathing forms air cavities for ventilation of the insulation and reduces the deformation loads from the frame to the OSB board.

Insulation is placed between the frame posts. A wind and waterproofing membrane is attached over the studs and insulation, which easily allows moisture to pass through. Next, the sheathing and OSB boards are attached to it.

Installation of OSB boards on a wooden frame with sheathing.

Installation of OSB boards on a wooden frame with sheathing. With this design, the slabs can be left unfinished; you can paint them, plaster them, or attach almost any façade material to them.

When fastening OSB boards without using sheathing, maximum rigidity of the wall structure is achieved. In this case, it is recommended to attach the wind and waterproof membrane behind the OSB board, then install the sheathing to create a ventilation gap and install façade material on it, such as siding, boards or decorative panels. OSB boards are attached to a wooden frame with nails at least 2.5 times longer than the thickness of the OSB sheet.

The advantage of using nails over self-tapping screws when fastening OSB on the outside of a house is justified by the fact that nails better tolerate deformation of OSB sheets under atmospheric influences.

Technology for attaching OSB sheets to a wooden frame without the use of sheathing.

Technology for attaching OSB sheets to a wooden frame without the use of sheathing. Fastening OSB boards to a metal frame

Fastening is carried out similarly to the option with a wooden frame. When attaching slabs directly to metal frame use metal screws 10-15 mm longer than the thickness of the OSB sheet.

General rules for installing OSB boards to the wall

Regardless of the chosen method of fastening OSB sheets, there is general rules, compliance with which will ensure maximum strength, reliability and durability of the cladding structure.

- Self-tapping screws should be screwed in at a distance of 10-15 cm from each other and at least 1 cm from the edge of the slab.

- A 10 mm gap is required between the bottom slab and the foundation to prevent water accumulation.

- The slabs cannot be joined closely to each other; a gap of 2-3 mm is required between them so that the slab can expand freely due to changes in humidity.

- All door and window openings are cut with a jigsaw or circular saw, but if you need perfectly even joints and cuts, then you can ready-made sizes and OSB sheets arrive at furniture workshop, where for a small fee they will cut your sheets on a sawing machine evenly and precisely to size.

OSB boards are a modern building material universal purpose, best suited for external and internal decoration of walls of residential or industrial premises.

The material is made of resin and compressed wood shavings. It is in great demand today due to its many positive properties: strength, durability, environmental friendliness, moisture resistance, ease of use, etc. Such panels from German, Swiss, Austrian, and Canadian manufacturers have proven themselves well. It is necessary to consider in more detail the entire process of interior finishing of OSB walls.

Preparatory work before installing OSB boards

Before finishing the walls with OSB, it is necessary to carry out thorough preparatory work. It consists of:

- in the selection of materials and tools;

- in the installation of sheathing.

For preparatory and main work you will need materials and tools:

To work with OSB boards you will need a jigsaw, a screwdriver, spatulas, and a brush.

- wooden beams 4x4 cm;

- OSB boards 1.2 cm thick;

- screwdriver;

- self-tapping screws;

- heat insulator – mineral wool;

- antiseptic against rot;

- jigsaw;

- primer is not on water based;

- brush;

- putty;

- spatulas;

- varnish or paint for finishing.

A few words should be said about the material used - OSB boards. Another name for them is oriented strand boards. Wooden shavings inside the material are arranged in 3 rows, each of them perpendicular to each other. This provides the material with high strength. Another important property, water resistance, depends on the connecting element. Recently it has become more environmentally friendly due to the use of resins. OSB panels do not have the disadvantages of their predecessors - chipboard, plywood, which must be processed before installation by special means against rot. Panels specially polished by the manufacturer have an aesthetically more attractive appearance.

The panels can be fastened using self-tapping screws, dowels, and nails.

When installing slabs, preference is given to self-tapping screws, since the reliability of fastening increases sharply; the work will require a much smaller number of them than, for example, nails; if necessary, you can turn them back out. Now you need to install the sheathing on the walls wooden beams using a screwdriver and self-tapping screws. The distance between the supports should be approximately 40-50 cm. Such work usually does not cause any difficulties. If it is necessary to insulate the walls, then before the start of the main work, after installing the sheathing, the sheets are laid out mineral wool. After the preparatory work, the walls are finished with OSB slabs.

Return to contents

Interior decoration of room walls with OSB panels

Finishing walls with OSB boards is reminiscent of installing plasterboard sheets. You just need to take into account that OSB boards weigh much more than plasterboard sheets, and therefore require more reliable fasteners.

The panels can be installed in 2 positions:

- vertical;

- horizontal.

When producing slab finishing near doors and window openings It is necessary to leave small gaps of approximately 3 mm. It is best to use panels with tongue-and-groove edges for work; in this case, an additional groove-tenon connection will occur, which will ensure ideal flat surface walls

Wood screws are screwed in with a screwdriver at a distance of approximately 15 cm from each other, departing from the edge of the slabs at least 1 cm. If necessary, adjusting them to the required dimensions, you can cut the panels with a jigsaw.

After the fastening has been made, it is necessary to finish the walls from OSB. It should be noted that here we are considering slabs that have already been sanded by the manufacturer; if not, you need to sand their surface yourself using fine-grained sandpaper.

The most common way to finish OSB panels is to putty them, with which you can remove all the cracks present at the joints. The putty can be acrylic, latex, or gypsum based. It is best if the putty is colorless. Before filling the walls, they must be primed.

Further finishing of the walls may consist of painting or varnishing them. Experts recommend that if varnishing the walls is chosen, use matte varnish. The walls are varnished in 3 layers with high-quality drying of each of them.

Thus, OSB boards are one of the most popular today modern materials thanks to the fact that they have many positive properties, easy to install and affordable.

Materials made from wood waste have all the positive qualities of natural materials and more. low cost. Modern technologies made them stronger and more resistant to water and fire. Frame construction is becoming more and more popular. People like a house made of OSB boards, it is warm, light, and retains the smell of the forest for a long time. By ordering parts in accordance with the project, you can build a house with your own hands without lifting equipment and wet work.

How to build a house from OSB?

Improved qualities of natural wood in OSB panels

Wood surpasses all others in its qualities that create comfort in the home. natural materials. Its disadvantage is swelling from water and fire hazard. Rodents and insects love to live in warm walls, prematurely destroying them.

When producing solid wood products, a lot of waste remains:

- small pieces of wood;

- branches;

- wood chips;

- sawdust;

- shavings.

They are sorted and combined in various ways and pressed. The result is panels that take the best qualities of wood.

The production of OSB panels uses large chips, accounting for 80% of the mass of the slab. It is laid in layers, orienting the direction of the outer sides along the sheet. The internal chips are arranged transversely. Perpendicularly oriented fiber eliminates warping and shrinkage of the panels. Pressing and impregnation with synthetic resins makes the material more resistant to fire. It does not ignite and does not support combustion, but it chars and collapses. This does not release toxic substances.

OSB panels for house construction

In construction, based on strength and moisture resistance, there are 4 groups of OSB panels. The table shows the main use of each type.

| OSB board class | Strength | Moisture resistance | Scope of application |

| OSB-1 | low | low | furniture manufacturing, interior partitions, interior elements |

| OSB-2 | average | low | only in dry rooms |

| OSB-3 | average | high | external and internal wall cladding, partitions and finishing in wet rooms, bathrooms |

| OSB-4 | high | high | all types construction work, including plinths and basements, reusable formwork |

Walls made of OSB panels retain heat and absorb noise slightly worse than natural wood. The material has high environmental friendliness. The lack of wood in its combustion and absorption of moisture is eliminated by impregnation, additives and pressing.

When making house parts from panels with your own hands, you should take into account the specific location of the fibers and hardness. OSB cuts and drills worse than solid wood.

Frame houses are cheaper and quick to install

Frame house

The construction of residential buildings from OSB boards is carried out according to an approved project. Blocks are made at the factory and labeled. A light foundation is made on site and then the frame of the house is mounted on it and sheathed with the resulting parts. The insulation is installed during the production of blocks. This method of construction has a number of advantages over standard brick buildings.

- You can move into the house immediately after laying the roof and do the finishing or simply varnish the inside walls.

- Construction is done using the dry method and takes less than a month, including the creation of the foundation.

- A frame house is 3–5 times lighter than a brick one. A light foundation at a shallow depth or a support-column foundation is made under it.

- There is no need to use lifting mechanisms to erect walls and roofs.

- The smooth surface of the panels is finished without complex plaster. Putty is sufficient for painting and wallpapering.

- The material of OSB panels is used for insulation of brick and wooden house. Additionally, polystyrene foam or other extruded plastic is placed inside. The heat in the house is retained better than with brick walls 1 meter thick.

- It's comfortable inside the house, the walls breathe.

- They don't shrink.

- There is no waste during installation; the blocks are made to size at the factory.

- The cost of a frame house made of OSB is significantly lower than a brick one.

Frame houses also have their disadvantages. If you want to have a basement in your house, you need to do strip foundation to its entire depth or dig and lay out the walls separately, at a distance from load-bearing structure. It is more difficult to hide the wiring with your own hands. Heavy equipment and cabinets cannot be hung on OSB walls.

Construction of frame houses

We build a house from OSB ourselves

If you want to build a house with your own hands from OSB, then you will need helpers. The optimal number for work is 4 people. You can get by with a minimum number of workers - 2 builders. Then one must have experience in assembling frame houses. The second is to be able to understand it, present it, hold it.

- Placed on the foundation waterproofing layer. There is a lower harness on it.

- The racks and corners of the walls are attached, and a diagonal fastening is made to prevent the structure from “folding.”

- The top trim is installed.

- Floor and ceiling beams are laid.

- The frames of the openings are installed.

- The rafters are installed and sheathed.

- The floor and ceiling are covered.

- Sheathing is done with OSB panels.

- Sealing extensions are installed at the corners and joints of the panels.

When building with your own hands, the walls outside and inside of a residential building are sheathed separately. Insulation is laid between the layers of OSB, wires and life support systems are laid.

Advice! Self-tapping screws do not screw into OSB well and become warped. It is advisable to drill a hole for them. The drill diameter should be smaller than the screw thread.

For thermal expansion A gap of 3 mm is left around the perimeter of the floor between the panels and racks. There is a gap of 2 mm between the plates themselves along the entire sheathing. Wall panels don't reach flooring 10 – 12 mm. The finishing gap is closed with skirting boards.

The floor panels are laid on the beams across their location. There must be at least 3 crossbars under each OSB slab. Along the length, the ends of the sheets are connected on a beam. Both edges are secured with self-tapping screws. The pitch between the floor beams is 500 - 600 mm.

A house built from OSB panels can easily withstand outside temperatures from 40 degrees below zero to the same heat reading. The comfort of the buildings is not inferior brick buildings with insulation and wooden houses. The walls breathe, removing moisture out. The air inside remains fresh. Fungus and mold do not appear.

OSB sandwich panels

Sandwich house OSB panels with your own hands

OSB sheets are also used to create sandwich panels. The space between two slabs of pressed wood chips is filled with expanded polystyrene. Such a house is assembled by a specialized team. Sheathing, installation and fastening are used similarly to the construction of buildings made of sandwich panels.

The frame and lining of the openings are made of boards 3 cm thick. Start profile The width of the strip is equal to the groove in the end of the panel. It is attached along the entire perimeter to the foundation with metal brackets. The panels are fastened together with timber. They are fixed to the posts with long screws.

The interior of buildings is inferior to houses made of OSB boards in aesthetics. Therefore, such technologies are rarely used for residential buildings.

OSB boards, also known as OSB boards, are increasingly used for arranging walls and interior partitions in houses. Not surprising, because it is a lightweight, inexpensive and very practical building material. Therefore, the question of their finishing arises. Here we will look at the main methods of finishing walls made of OSB sheets inside the house.

You can read about the technology of attaching OSB boards to the walls inside the house on the page:.

The walls in the house are made of OSB (OSB) sheets.

The OSB board itself has a distinct wooden structure. Therefore, it can be left unchanged, covered only with stain to further emphasize the beauty of the material or give it a different shade. If you plan to paint, wallpaper, tile, etc., then it is important to remember one feature of oriented strand boards. This is the presence of a special impregnation of wax, resins, paraffin, with which any finishing material connects poorly. Therefore in such cases prerequisite at OSB finishing is a preliminary primer.

More details about what OSB or OSB boards are can be found in a separate article:.

The main methods of finishing walls made of OSB boards inside the house

Varnishing

Varnishing or varnishing is a method that allows you to preserve appearance slabs and increase its moisture resistance. It is suitable for finishing walls in damp rooms. Before applying varnish, it is recommended to level the surface properly using sandpaper, and prime.

Priming OSB boards. You can use a brush or a paint roller.

Priming OSB boards. You can use a brush or a paint roller. Coloring

Painting is the simplest and most affordable option. To do this, use water-based paint compositions (water-based, acrylic or latex paints). They allow steam to pass through perfectly and thus provide a good microclimate in the room. Before proceeding directly to painting the surface, it must be properly prepared. First, apply two layers of primer and then level it using wood putty. After this, paint should be applied.

More details about the types of paints used and the technologies for their application are described in a separate article:.

Wallpapering

Gluing wallpaper is a complex process that requires strictly maintained technology. First, two layers of primer are applied to the OSB board, then putty and only then wallpaper glue with the addition of PVA. This will give the adhesive greater strength and a guaranteed result.

Decorative putty

Decorative putty is a finishing of OSB walls inside the house, which also allows the walls to breathe, creating optimal conditions indoors. First, the surface of the slabs must be treated with a special primer, to which PVA glue, interlining and a little putty are added. And only then do they begin to putty;

Laying ceramic tiles

Thus, there is nothing difficult in finishing OSB boards, provided that all the rules for working with them are followed. And the choice of finishing method depends only on taste preferences.