Installation of any finishing material– this is not a job that needs to be approached exclusively creatively. In order for the floor covering to properly serve the period stated by the manufacturer, you should first read the instructions on how to properly lay linoleum. And, of course, follow all the rules and recommendations prescribed by it.

Finishing elastic coatings have been actively used in floor finishing for more than 2 centuries. Available:

- Heterogeneous - multilayer linoleum products consisting of a base (foamed vinyl chloride polymer or felt made of synthetic threads), a front layer ( thin layer calender fabric with a certain decor) and transparency (protective surface coating). Additional layers are often added (reinforcing, improving strength).

- Homogeneous - single-layer coatings with an extremely high degree of wear resistance with a uniform structure and uniform decor throughout the entire depth of the material.

To choose the right linoleum yourself, before going to the store, decide on the following parameters:

Type of coating. There are 2 types of products used in the household sphere

Coverage type. Available for sale:

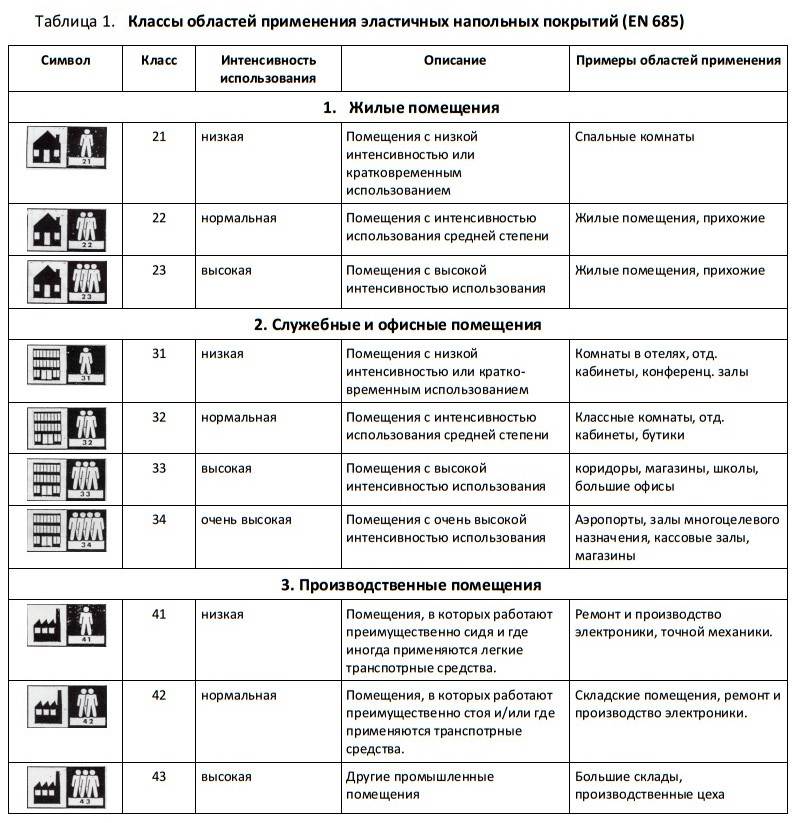

Wear resistance class. As can be seen from the table below, each room is assigned a specific load category. That is, the level of traffic, the presence in the room of heavy furniture, interior items on casters, etc.

For example, for bedrooms, class 21 finishing material is recommended for the floor because in these rooms people almost never wear heels - only slippers. Therefore, it is not the wear resistance of the top layer that is important, but the dense structure of linoleum. At the same time, in kitchens and corridors, as well as living rooms with massive furniture, it is not necessary to purchase semi-commercial or commercial coatings of 32-33 classes. Enough high-quality linoleum class 23 or 31 from famous manufacturer: Tarkett, Juteks, Forbo, etc.

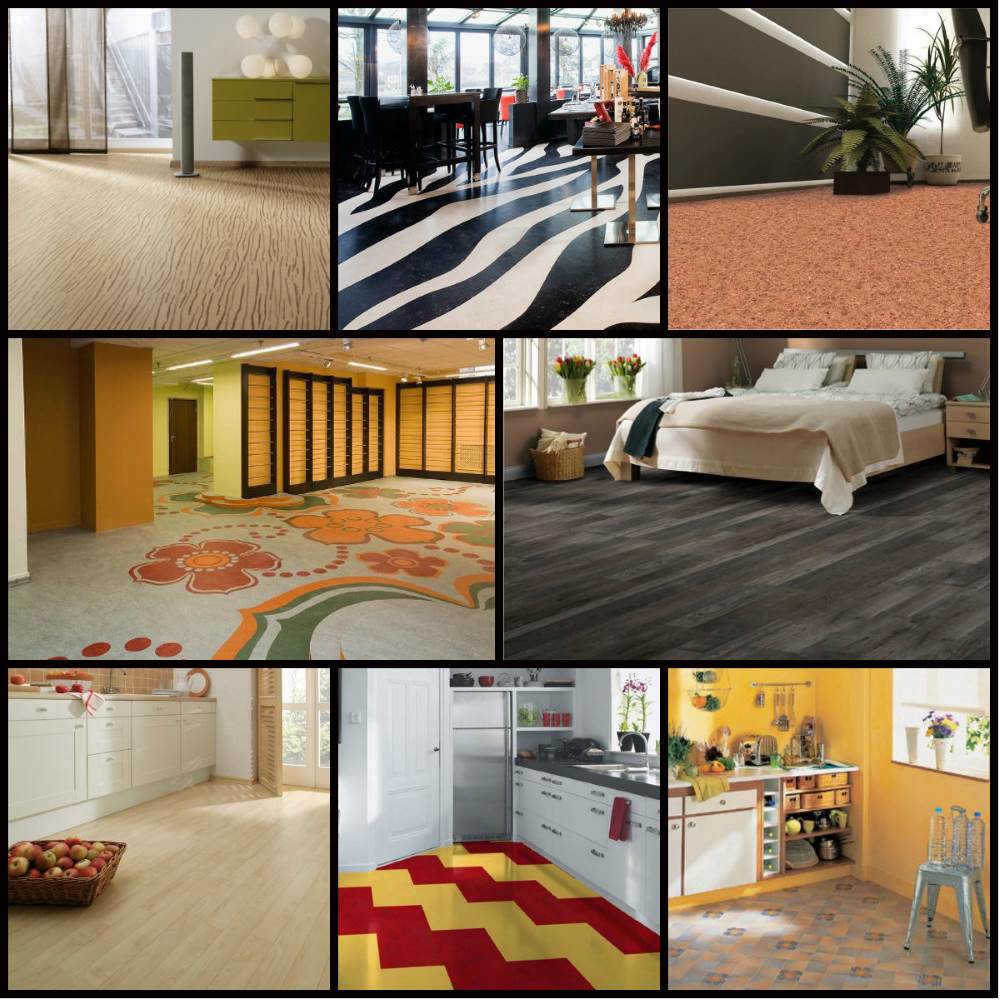

Design. This criterion can be called perhaps one of the most important. Depending on your choice, the room can become brighter and visually larger. And vice versa, more austere or even gloomy, if it is not diluted with an abundance of light “blobs” in the form of walls, furniture, etc.

Base type. The base layer of foamed PVC is considered universal, and the felt layer is warmer. However, the polyester base does not like water - when wet it emits bad smell, fades, takes a long time to dry out. Therefore, it is not recommended to lay linoleum on a fabric or combined base in rooms with high humidity(kitchens, balconies).

Canvas size. Measure maximum length and the width of the floor in the room, including niches and doorways. If the walls are uneven, add a margin of 5-8 cm to each indicator plus 1-2 cm for shrinkage (PVC products are rolled up hot, and after unrolling trading floor“shrink” a little; this is a natural physical process). In the case where several cuts are needed, make sure that the blades are cut in front of you from one roll or, at least, from rollers of the same batch. Different series may differ in tone or structure, which is not a defect or defect in the product.

If the room is large and the joints of the canvases run in the center of the room or offset, try to choose a design with minimal repeat (a repeating part of the pattern on the surface of the linoleum). This will reduce the amount of waste when adjusting the pattern.

When handing out a linoleum cut, carefully inspect the surface for minor damage and defects in the front layer: there should be no scratches, dents, dots or stripes, asymmetrical or blurry patterns, etc. Linoleum, like any elastic material, is rolled up with the front side inward for subsequent transportation. It is strictly prohibited to bend or fold the cut into an envelope. This can lead to irreversible damage to the full thickness of the finishing material.

An interesting article about choosing linoleum according to quality criteria:.

How to lay linoleum correctly: choose the appropriate method

Both natural and PVC coatings are laid in almost identical ways, so we will consider the installation technology of vinyl chloride products, as the most common.

If the base is carefully prepared, it corresponds basic requirements, then installation is carried out according to the recommended instructions:

| Fixation method | Materials used | Pros | Cons |

| Adhesive | Water-dispersed special glue for polymer based with excellent adhesive properties | Reliability Durability Resistance to bending, shearing and twisting deformations |

Difficult dismantling |

| PVA is a universal and inexpensive glue with a pungent odor. | |||

| Synthetic latex-based universal mastics with a biocidal effect | |||

| On double tape (for concrete floors with hardened surface) | Connecting linoleum with the base around the perimeter and at the joints in doorways made using adhesive double-sided tape | Partial resistance to shearing, stretching | Insufficient connection reliability |

| Simple, perimeter fixation | Linoleum is laid on the surface and pressed to the base with skirting boards | Fast installation, minimal costs | Unreliable and short-lived connection |

Surprisingly, on the Internet you can find very extreme methods of fixing natural and PVC coatings - using self-tapping screws, sealants, “ liquid nails", a furniture stapler and even linoleum (roofing) hardware. These options are ineffective and can only be used if the flooring material is purchased for temporary flooring - for 1-3 months

Required tools and materials

To lay linoleum yourself, you will need the following kit:

- Compositions for repairing base defects or leveling surfaces;

- Construction vacuum cleaner;

- Knife for cutting coating with hook or construction knife (with replaceable blades);

- Steel lath or level;

- Tape measure and marker;

- Notched trowel or short-haired roller for applying adhesive;

- Lapping board, sail trowel or clean roller (rubber or velor) for smoothing linoleum to the base floor;

- Masking tape or double-sided tape;

- An adhesive composition for fixing linoleum to the base, as well as an adhesive or strengthening primer;

- Adhesive for joining seams. Best to buy special compounds cold welding series. They fuse the canvases, and the joint turns out to be monolithic, almost imperceptible;

- Set of skirting boards with fittings and decorative thresholds made of metal or PVC.

How to lay linoleum with your own hands

- Room temperature – not lower than +15 °C, base temperature – from +14 °C to +25 °C.

- Relative air humidity – up to 75%.

- The interval for acclimatization of the spread coating is at least 24 hours, in winter time– up to 3 days.

Acceptable base types:

- monolithic concrete base or floor slab with a smooth surface without defects;

- cement-sand screed, anhydrite and others with a surface strength index of at least 150 kg/cm².

- Prefabricated dry coating from sheet rigid materials (gypsum fiber board, MDF, moisture resistant plywood or chipboard).

We'll tell you how to lay linoleum on any of the permitted substrates.

Preparing the base floor

According to manufacturers' requirements, the floor should be:

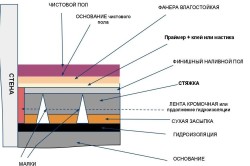

- Dry (humidity of cement-sand screed - up to 4%, anhydrite - no more than 0.5%, precast - up to 8%). If necessary, waterproofing primers can be used.

- Durable (the indicator is selected based on the planned loads, varies between 150 - 300 kg/cm²).

- Smooth (difference no more than 2 mm for every 2 meters of surface according to SP 29.13330.2011/SNiP 2.03.13-88). There should be no holes, cavities, tubercles, sagging or other similar defects. Leveled using screeds, self-leveling floors or repair mixtures(pointwise).

- Monolithic, that is, seams, cracks and other damage must be repaired in advance.

The floor heating system is turned off 3-5 days before the start of work. Old coatings, including asphalt, paint and varnish, textile and the like, are removed, and the surface is vacuumed. You can prime the base before applying the glue. This will ensure uniform absorption and strengthen the top layer.

We would like to remind you that we only lay linoleum on a hard surface. You cannot install insulation and soft substrates under the material. This violates two laying rules at once - evenness and hardness.

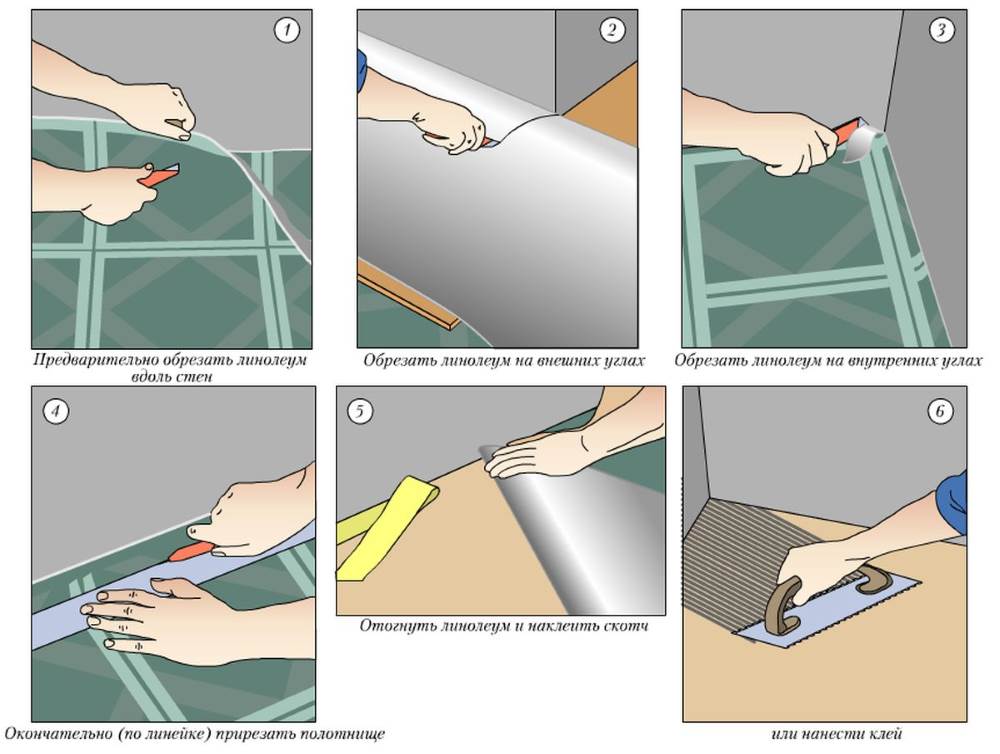

Flooring adjustment

Very easy to work with smooth walls. The linoleum is laid so that it fits tightly to the wall in width or length, carefully leveled, fixed around the perimeter using double-sided adhesive tape, and the excess is carefully cut off. A small compensation gap is left at the edges - 0.5 - 1 cm.

If the walls are uneven, then the coating is “rolled” a few centimeters onto the vertical enclosing structure, pressed to the floor with a metal strip and gradually cut off the excess.

Trimming external and internal corners is carried out as follows: the flooring material must be pressed to the junction point connecting the walls and the floor, a cross-shaped cut of 3-5 mm must be made, and the covering must be carefully “pulled apart” to the sides. You should work without haste, because the excess is easy to remove, but the missing part is very difficult to restore.

Please note: in order for the seam in the area where the two panels join to be invisible, you must:

- combination of decors. Designs without a clearly defined pattern (sand, granite chips, flock) it is recommended to lay it reversely, that is, in opposite directions. But products with a surface like wood, textiles, marble, tiles and others must be mounted in one direction with mandatory adjustment according to the repeat, which can reach 80 cm.

The spread piece must be carefully bent and rolled into a roll half its length. Remove unnecessary tape. Apply with a notched trowel or roller adhesive composition, wait the time specified in the instructions (10-30 minutes), slowly roll out the linoleum and smooth it with a roller or lapping board for uniform gluing and removal of air bubbles. Likewise fix the remaining half of the flooring material. After 1-3 days, if necessary, treat the joints with “cold welding” or PVA glue in accordance with the instructions on the box.

If the coating is fixed with double-sided tape, then after adjusting along the perimeter, the edges are bent and glued to the base adhesive tape, smoothed. Next is removed protective film, linoleum is applied and rolled.

The finishing touch is the fixation of decorative skirting boards and thresholds. They will decorate the room and give it a finished, seamless look.

Advice! If you need repairmen for repairs, there is a very convenient service for selecting them. Just submit in the form below detailed description work that needs to be done and you will receive offers with prices from private craftsmen, repair teams and companies by email. You can see reviews about each of them and photographs with examples of work. It's FREE and there's no obligation.

One of the simplest and quick ways finish the concrete floor - lay new linoleum. Construction stores offer a wide selection of this material in various thicknesses, textures and colors. Even the most demanding buyer can choose something to his liking.

Choosing linoleum for laying on a concrete floor

Linoleum is classified according to operational characteristics and the composition of its constituent components. There are three classes of this material on the market - household, semi-commercial and commercial linoleum. Each class has its own parameters of resistance to wear and operation. The thicker the linoleum, the stronger it will be and the longer it will last.

Household linoleum is used for laying in rooms where there is low traffic intensity. It is most often used in residential areas. The semi-commercial class is used for installation in office premises, schools, offices, residential buildings, where the walking intensity is low or medium. The most durable is commercial linoleum. It is used in premises where traffic is very intense (hotels, shops, large offices, educational institutions).

Types of linoleum

- Natural linoleum - has a base made of burlap (jute fabric) impregnated with linseed oil. The material contains natural resins various trees, natural dyes, limestone, wood flour. According to standards, natural linoleum must contain at least 30% linseed oil. This material is absolutely safe for human life; viruses and bacteria cannot have a destructive effect on it. The wear resistance of this material is very high. Natural linoleum is difficult to ignite. This linoleum is very durable, so it can be laid in any room.

- Polyvinyl chloride linoleum is a coating made from synthetic polyvinyl chloride polymers, fillers, cheap plasticizers and coloring pigments. This is the most cheap look linoleum. It gives off an unpleasant chemical odor and is highly flammable.

- Colloxylin linoleum has good elasticity, is resistant to moisture, but is quite thin and flammable. It is prohibited to be used in medical and children's institutions.

- Rubber linoleum - the composition includes rubber rubber mixtures. The main advantage of the material is its resistance to water and slipping. This material is most often used for installation in the bathroom and toilet.

- Alkyd linoleum - the base is made up of woven materials and a layer of alkyd resin. There is a wide selection of textures and colors. This material has excellent soundproofing characteristics. However, it does not tolerate sudden temperature changes and immediately begins to crack. Therefore, it can only be installed in warm rooms.

How to lay linoleum on a concrete floor yourself

Laying linoleum on the floor is a fairly simple operation that does not take much time and effort. The main thing is to prepare the surface well, perform the entire sequence of actions correctly, select quality material and tool.

Tools needed for laying linoleum on a concrete floor:

- Roulette.

- Marker.

- Metal meter ruler.

- Sharp knife.

- Spatulas.

- Glue.

- Skirting boards, corners.

- Brush and roller.

How to lay linoleum - work technology

- If the concrete floor is painted or treated with some other product, it is not necessary to remove it. Linoleum is placed directly on top of this covering. If there is carpet or carpet on top of the concrete floor, then, of course, it must be removed, thereby cleaning the floor to the base. If you do not remove the old coating, then perhaps it will be softer to walk on, but sooner or later the dust and dirt it contains will penetrate the air.

- Garbage with concrete covering should be swept thoroughly. It is advisable to clean powerful vacuum cleaner or a clothes brush (this allows you to remove small particles). Next, the floor should be primed. Due to this, the surface will be strengthened, and the concrete floor will be in a bonded state for a long time. Priming can be carried out with a fur roller, which is placed on long handle. It is better to coat the joints and corners of the walls with a brush. After the surface has dried, you can only walk on it in clean shoes.

- Concrete screed will be the ideal base for any selected floor covering, including linoleum. Thanks perfect flat surface you can install it quickly and easily. If you put linoleum directly on concrete, the floor can be very cold (an exception is linoleum, which has a thermal insulation pad). You can put sheets of plywood or chipboard on a concrete base, this will significantly improve the situation.

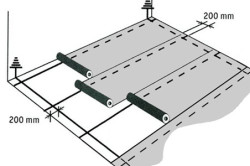

- First of all, a film is laid on the concrete for waterproofing. It must be laid so that the sheets of film overlap each other by 20-25 cm. It is also necessary to ensure that the approach to the wall is 5-6 cm. If you want to improve sound insulation, a layer of foamed polyethylene should be laid on the floor (on top of the film). Chipboard sheets or plywood can only be laid on a perfectly flat concrete floor, otherwise the material will deteriorate very quickly and damage the linoleum. Plywood and chipboard are attached to the concrete base using plastic dowels. To prevent the top of the screw from protruding, you can use a larger diameter drill to make a chamfer inside the hole. If laying chipboard is not included in the plans, then it is enough to purchase linoleum, the size of which is slightly larger than the room, and use skirting boards to secure it around the perimeter of the room. It is advisable to glue the wallpaper before you decide to lay linoleum.

- When purchasing a coating, you usually have a choice between rolls that are 4 and 3 m long. It is better, of course, to work with a coating that is 3 m long - it can be easily transported and marked. If the room has non-standard sizes, then the marking becomes significantly more complicated. Therefore, it is advisable to draw up a plan on paper in advance on how best to lay linoleum. After this, all dimensions are transferred to the coating using a tape measure and marker. Next, using a sharp knife, cut out the panels. Pieces of coating are laid on the concrete floor and leveled well. You need to walk on the surface in this position for a week. After this time, the waves and bubbles should disappear and the coating can be glued.

According to the technology, there is no need to apply glue. However, if there are seams, they must be taped. If the floor surface is well primed, the glue will adhere very firmly. If the floor is poorly primed, the coating will not adhere, and the glued surface will be covered with sand and fine dust. There are two ways to apply glue - when the surface is completely covered and when a mesh is drawn. The last method is best used on thick coatings. The seams must be taped with special care.

If the coating does not glue, it should be firmly nailed and secured around the perimeter, and then trim off the excess pieces. The work is completed by securing the plinth. It is best to purchase plastic skirting boards that have a cable rope. Corners of the same color are matched to the baseboards. Skirting boards must be sealed, otherwise the dust that is in the lower layer of the floor will constantly get into the air.

Laying linoleum on a concrete floor is quite a feasible task for many.

The main thing is that before starting work, the floor surface is dry, smooth and free of flaws. If there are cracks, depressions or differences in floor level, then before carrying out work it is necessary to use a leveling mixture and wait until it dries completely. Preparation for laying the coating usually takes a considerable amount of time. longer time than the main process. Laid according to technology quality linoleum will serve its owners for many years.

- What to choose?

- Laying linoleum yourself: recommendations

How to lay linoleum with your own hands? In fact, everything will turn out very easy if you follow certain instructions and advice from professionals. Laying linoleum is much easier than, for example, laminate. And so, you bought linoleum, it lies waiting in the wings. And the whole family looks at you thoughtfully with the same question, how to lay linoleum? Maybe call a professional guy to do it quickly and efficiently? Stop thinking, you can do everything yourself, which will “delight” your home budget and feel the sea positive emotions from what was done. The main thing is to think about everything in advance and slowly change your home beyond recognition.

Linoleum is a cheap and practical material. They can transform any room or space. Today on the building materials market there is quite a rich selection of styles and color solutions. This allows you to implement any design ideas. In addition, linoleum material is distinguished by high strength and the ability to withstand considerable mechanical load. It remains to figure out how to lay linoleum.

Preparation for installation work

![]()

The procedure for laying linoleum at the front door.

When carrying out work on laying linoleum, you need the following tools for marking and adjusting the fragment:

- ruler and tape measure;

- pencil;

- stationery knife;

- scissors.

When you are laying linoleum flooring in a large room (more than 25 square meters), you should stock up on additional tools. At the same time, in rooms with a smaller area, gluing is not used, since free installation is performed. This:

- glue;

- double-sided tape;

- roller;

- spatula.

The entire possible set of tools is listed, it all depends on what and how you will lay the linoleum.

The first step in preparing for work is to vacate the premises. Take out large furniture and all kinds of objects in the room. The space should be cleared to the maximum. If work is carried out in two-room apartment, then the linoleum spreads one by one. And the furniture is moved to where nothing is being repaired at the moment.

You have vacated the room, then you need to think about preparing the floor surface. And it doesn’t matter what kind of floor covering you had before, you need to make sure that before final installation, the surface on which the material is spread is cleaned and leveled. It is necessary to remove the skirting boards along all the walls of the room, since the laid covering will be adjacent directly to them. If you plan to use the baseboard again, remove it carefully so as not to break it. In this case, you can even number the slats on the back side by placing a similar number on the wall to make it easier further work. If renovation work were produced quite a long time ago, and it is not possible to remove the skirting boards intact, it is better to purchase new ones. Aesthetics will only benefit from this.

Now it’s worth paying attention to the floor itself. If you decide to major renovation, That ideal option Self-leveling floor will be used. This option is optimal if the base is made of concrete or cement screed. But in most cases, linoleum is spread over a board or drying parquet. And if you do not plan to completely remove the old flooring, choose one of the options for eliminating unevenness:

- Use of chipboard sheets.

- Strengthening falling parquet strips.

- Using self-leveling floor technology with special leveling compounds.

A big problem with old floors is squeaking. Therefore, when making repairs, attention should be paid to this.

The only goal pursued by everyone preparatory work, is to achieve a perfectly flat and clean floor surface. Protrusions, depressions, all kinds of irregularities and debris on the base of the floor will certainly make themselves felt when covering, appearing in places of the most intense wear. You now know about ways to level the surface, and cleanliness can be achieved with a vacuum cleaner and wet cleaning.

It is important when laying linoleum to comply temperature regime, which varies from +15 to +25 ºС. At lower temperatures, the material may lose elasticity and become brittle. Pay attention to this if you are doing repairs in winter. Even if the room is warm, allow material brought in from outside to warm up. The lower outside temperature, the longer the warm-up time will be, up to 12 hours. Before work, spread out the roll and let it rest. This way you will avoid unwanted “waves”.

Return to contents

What to choose?

A short digression to the actual installation of linoleum will be advice on choosing the material: linoleum and substrate. When choosing the first one, you need to make a selection commensurate with the loads that will fall to its share. The shoes that will be worn on the linoleum material and even air humidity are also taken into account. Based on this, choose the thickness of the coating. The thicker it is, the stronger it is, of course. For example, a coating with a thickness of less than 3 mm has almost minus resistance and will deteriorate critically quickly under intensive use.

Often when using linoleum, a backing is placed underneath it. In most cases this cork backings. When using them, the effect of easy walking on the floor is achieved. But at the same time, heavy objects will leave their unwanted marks on it. Also, jute or linen materials look good as a substrate. They are pre-treated with an antifungal compound and are provided with fire resistance. The use of a backing is recommended if the linoleum is without a base. In this case, insulation is mandatory. Otherwise, substrates are not used, since they do not have sufficient mechanical strength and rigidity.

In many advertising articles devoted to PVC coverings, commonly referred to as artificial linoleum, you can often read that “linoleum does not have to be glued to the base, it is enough to simply lay it on the floor.”

Let's make some amendments right away. Due to the confusion of the terms used, it must be noted that linoleum, made using ancient technology from natural components, must be firmly attached to the floor, that is, with glue or mastic. As for the more common PVC coatings, they are conventionally divided into household and commercial.

Learn more about the differences between these two types flooring materials, we'll talk a little later. For now, let’s just note that only thinner household types of PVC coatings can be in “free flight” (without rigid fastening with glue), while commercial series are necessarily glued to the floor.

The technologies for laying linoleum and PVC coating differ little from each other. Whatever your choice, before you design it, you will have to prepare the base and the material itself. But first, a few recommendations.

Firstly, It must be remembered that laying materials of both types can be done at temperatures above 15 degrees.

Secondly, Before laying, the roll must be rolled out on a dry and clean base and kept in a free state for 1-2 days. However, there is no need to rush, if the coating was brought from the street where the air temperature was below zero, it should rest in a roll for a day.

You also need to think in advance about the linoleum joints, if any. Or rather, about how to hold them together. Along the edges the covering is pressed with skirting boards. By the way, if you don’t want to tear them off, you can simply stuff a bead or fillet close to the baseboard, which will press the linoleum. Paint it the same color as the baseboard, and it won't attract attention.

It is much more difficult with joints located in a visible place in the room. You can glue pieces of linoleum at the junction with double-sided tape (branded only) or using " cold welding" with special glue. Or you can use a "linoleum profile" tape. The coating is inserted into it on both sides, the tape itself compresses it - and that's it. As they say, cheap and cheerful. However, there is a small drawback - thickness. Such a connection will look like small threshold.

Linoleum and PVC coatings can be laid on cement-sand screeds, lightweight concrete, flooring made of boards or chipboards and fibreboards, etc. But the bases must be smooth, dry, clean, without cracks. Coatings do not allow moisture to pass through, so if you stick them on a base that is not dry enough, moisture will accumulate under the material, destroying the glue and the coating itself.

The relative humidity of the floor can be measured with a hygrometer, and for PVC coverings it should not exceed 0.05%. On concrete base floors of the first floors and in wet rooms (in the kitchen, for example) waterproofing is necessary. When installing a "warm floor", the heating system must be turned on at least 4 weeks before laying the covering, but it must be turned off 24 hours before any surface preparation. The heating temperature during operation of the “warm floor” should not exceed 28C.

If the floor is concrete, then you can level it with cement. Most difficult option- this is a plank floor, linoleum is wiped along the protruding floorboards, so you need to use sheet material: fiberboard, plywood, etc. According to the principle: the greater the unevenness, the thicker the material that needs to be used to level them. Do not under any circumstances try to lay sheet materials on concrete floors - the joints will definitely protrude. To insulate the floor, it is better to lay it on concrete roll insulation from mineral materials.

So, we level the plank floor using plywood. After adjusting the size of the room, you need to walk around the plywood and check if there are any places where it bends under your weight. If there is, then it is worth placing pieces of fiberboard there and marking the treacherous place in order to exclude plywood fasteners here, since when deflected, the head of the screw will remain in place and can tear the linoleum. Then the plywood joints need to be adjusted in height and you can pick up a drill and screwdriver. After last screw Once you have found your place, trample all over the floor again and tighten the fasteners.

It is not advisable to lay these floor coverings directly on wooden boards, since if they bend when walking, damage to the coating will occur. But if the reason is wood covering, before laying linoleum, the boards must be carefully planed in all directions and then cleaned with sandpaper.

Sometimes linoleum spreads over parquet floors. This means that you need to carefully plan the protruding rivets and cover the seams and cracks with putty. Otherwise, all parquet defects will be imprinted on the linoleum. If the base covering is old, it must be re-laid so that the boards do not sag and damage the surface of the linoleum.

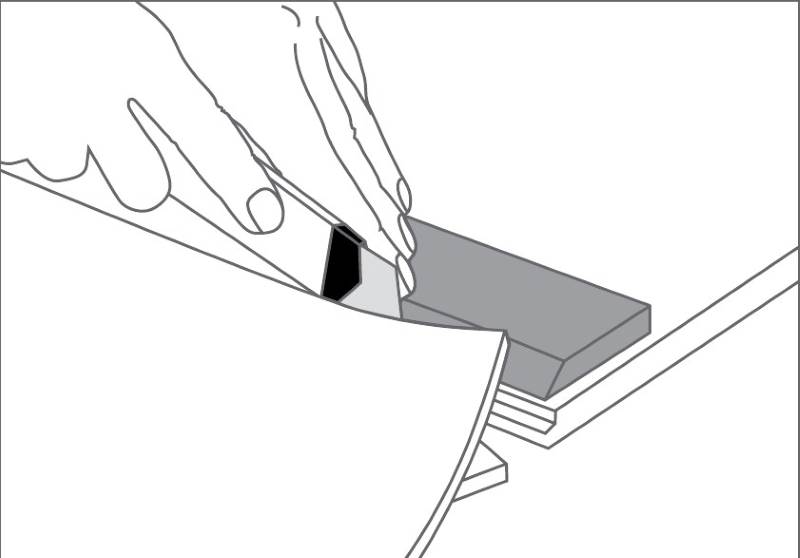

Before starting work, the coating itself should be prepared. To remove bulges and dents on it, it must be cut into pieces required sizes and iron each fabric with a hot iron from the wrong side. This must be done very carefully so as not to damage the coating. Cutting requires special knives with replaceable blades: trapezoidal blades are used for marking, and hook-shaped blades are used for final cutting. To determine required quantity material, you need to know the length and width of the strips. At diagonal laying a larger amount of waste is generated than with parallel; in oblique or round rooms - more than in rectangular ones.

Then the canvases are placed on top of each other and pressed down over the entire surface with some heavy weight. After 10-15 days, the linoleum will straighten out. When laying linoleum on wooden bases sheets should be placed along the slabs. The joining of the panels should be in the middle of the wooden slabs.

After the covering is cut into sheets of the required size and shape, you can proceed to their installation. When laying household PVC coating In residential areas where one or two pieces of covering are used, gluing is not required. The edges of this installation are covered along the perimeter with baseboards, and the seams are taped with double-sided tape. First of all, you need to remove the plinths, lay linoleum, adjusting the joints very well in width, carefully straighten it and press it with the plinths. It is better to glue the edges at the joints with mastic. Nailing of the baseboards is done 1-2 weeks after the flooring, when people walk on it and it presses smoothly to the floor surface.

Household covering should only be fully adhered when using more than two pieces of material and where moving heavy objects could cause bulging. Full gluing is also recommended for rooms with an area of more than 20 sq.m. if there is movable furniture (tables, chairs).

Linoleum like affordable, practical and durable coating refers to the well-known and widespread floor coverings. By covering the surface with such material, you can transform and ennoble any room beyond recognition. The main advantage of this coating is that you can install it yourself, without resorting to outside help . How to lay linoleum? This question is asked by most of the owners who have begun renovation work on the premises. To answer it correctly, it is worth study the main stages of installation and strictly follow the given instructions.

Preparing the base

Positive quality of linoleum:

- plastic;

- low cost;

- water resistance;

- high density;

- wear resistance;

- heat preservation;

- convenience and appearance attractiveness.

To understand how to lay linoleum correctly, you should first prepare mounting accessories:

- pencil;

- tape measure, ruler;

- large scissors;

- double-sided masking tape;

- knife;

- screws and screwdriver;

- glue;

- spatula and roller.

How to prepare the baseboard?

At the beginning of work, all skirting boards must be removed: they will interfere with laying linoleum close to the walls. Moreover, care is required here to allow the coating to remain unchanged, especially if these planks are to be reused. For convenience, the plinths should be numbered, so it will be easy to fix them in their original place.

What to do with old coating?

First you should analyze the condition of the previous flooring. Fallen into disrepair old parquet boards are being cleaned, the same goes for wood boards. Better surface For any linoleum there is a concrete floor and a substrate. But even here you should try: check with a level for possible differences in height, unevenness, recesses, chips. The unsatisfactory condition of the surface requires its careful leveling with a cement-sand composition. The thickness of such a coating should be no more than 5–7 centimeters. Next comes the finishing screed.

Regardless of the floor surface, it requires priming. As soon as the base dries, all debris is removed and the outer layer is washed. As a result of such actions The floor covering should be perfectly smooth and clean.

Taking measurements

Measuring carried out in advance, at the moment when the room is completely cleared of foreign objects. Having drawn up a schematic plan of the room, the resulting dimensions are recorded on paper with all the details in the form of protrusions, corners and other obstacles. The resulting dimensions should be add about 5 centimeters from either side. This is done to take into account the possible curvature of the walls.

Installation highlights

To understand how to lay linoleum correctly, you should adhere to the main installation steps, which will be discussed in detail below.

Rolling out rolls

Once the material has been selected and purchased, it should be placed in a vertical position and allowed to stand in this form for 24 hours. Such measures will help maintain the elasticity of linoleum. The next stage of coating acclimatization involves rolling out the roll. On a level surface, the material should completely straighten within 2 days.. Subsequent flooring is carried out at temperatures above 15 degrees.

Distribution of strata

The best option for placing sheets would be 1 single piece of material over the entire area. If it is impossible to avoid joining the surface, you should make a seam in the middle.

When laying sheets on the walls, it is important to take care to leave some margin where the coating will extend slightly onto their surface.

The presence of a perfectly straight factory cut will allow you to level the material, placing its end part towards the partitions while maintaining a distance of 5–10 millimeters, the edge of which is fixed with tape. Undercut coating will be needed on other walls.

If the material is presented in the form of pieces, then lay linoleum recommended by combining butt seams in the central part of the room. First a small one is made overlap at the edges, after which the material is carefully leveled around the perimeter. The pattern should be positioned longitudinally, relative to the walls.

Uncover

One of the sides that will not be cut is fixed with tape at the edge of the wall. Next is carried out cutting the material from other sides with an overlap of 3–5 centimeters, then the final cutting of the sheet is carried out. The layer is bent at all corners, the connection points are marked. Next, moving along the base and measuring 20–30 centimeters each, draw a straight line, unnecessary part is cut off.

The material should be cut extremely carefully: the permissible distance from the wall to the material will be 5–10 mm. This distance is caused by the possible expansion of linoleum during operation. Otherwise, irregularities in the form of waves may appear on the plane. The cut should be made with one stroke of the knife.

Stage-by-stage execution of work

Work plan:

The presence of a protruding corner in the room gives a reason to start working from this point. To begin with, the first, rough cutting is done, then the final leveling of the surface is carried out. If the need arises, holes are made for pipes, radiators, various angles.

Reinforcing activities

Rooms with small areas laid out freely— the linoleum is pressed down along the entire base with baseboards and thresholds. In large rooms, the material is glued with special glue. There are situations in which required reliable fixation such a base even in miniature rooms, where a significant load on the surface of the material is expected.

Sometimes used as a fastening for linoleum double sided tape is used. Of course, it will not hold the material as securely, however, it can be removed at any time.

How is the material glued? At first the floor is primed, then composition carefully spread over the floor surface with a spatula. After this, part of the linoleum sheet is glued with movements from the middle to the edges. Air bubbles are removed using a roller. Once one half is glued, you can start fixing the second part.

When laying floors from several parts of linoleum, it is important to ensure high-quality gluing of joints. Their fit should be as dense as possible. Most often in this case it is used cold welding technique. For this, colorless silicone glue is used.

Gluing parts along the factory edge makes seams perfectly even. Here you need to combine the sheets together and weld the joints. In the second option the strips are connected to each other, slightly overlapping each other. The coating pattern must be traced throughout the entire base of the material. After this, Using a ruler and pencil, mark the joining point in the central part. Next, a wooden ruler is placed under the marked point and the material is cut. Best for this use a ruler and knife, then the edge will be perfectly smooth.

At the beginning of the joint connection point pasted over masking tape , which will not allow the glue to leak onto the surface, after which it is cut along the seam. Then, welding glue is applied to the joint points. Drops of such a substance should fall not only on the alignment point, but also on the tape. After applying the glue, the adhesive tape is removed after 20 minutes. As a result, the end parts quality glued. Drops of unnecessary substance are removed from the surface of linoleum only after they dry.