Sawn timber yield rates from roundwood

In the report of the UN European Commission/FAO Timber Committee ECE/TIM/DP/49 on timber conversion factors different types forest products, in particular, the yield coefficients of sawn timber from round timber are given. These data, based on the experience of 16 countries, may well serve as guidelines for woodworking enterprises as world standards.Lumber covers a significant portion of solid wood lumber products. They include wide range products from unedged, freshly sawn to edged, dry, calibrated and planed lumber. The type of products produced has a significant impact on the yield of final sawn products from round timber. So from one cubic meter round wood you can get 0.8 m3 not edged lumber and only 0.4 m3 of dry edged, sorted and planed lumber. Therefore, various countries were asked to provide their yield ratios for various categories of lumber products to understand why national lumber yield ratios differ so widely.

For example, in Germany, 1.67 m3 of roundwood is required to produce 1 m3 of softwood lumber, while in the USA it is 2.04 m3. At first glance, it may seem that sawmilling in the United States is less efficient compared to Germany (the given coefficient indicates that the production of the same volume of lumber in the United States requires 22% more roundwood). But when taking a closer look at the production of the same types of lumber, such as rough lumber and dry lumber, it turns out that lumber yield rates in these countries are similar. This means that the differences in lumber yield ratios lie in the output various types finished products. Obviously, Germany produces more rough-cut lumber, while the USA produces more dry and planed lumber.

Some countries note that their countries' lumber production is recorded as freshly sawn to avoid double measurement of volumes for dry and planed lumber. This is in contrast to other countries, especially the Scandinavian region and North America, where the volume of lumber is most often given taking into account its final processing. This, for example, could result in a rough green lumber yield ratio of 1.57 (64%) or 1.75 (57%) for dry lumber or 2.27 (44%) for planed and finished lumber, as shown in the diagram below.

Tags and key phrases

the length of the board will equal 1.5 m3 of round timber, How many boxes come out of a cube?, consumption of lumber for 1 piece of cutting - how much is the waste?, Output from 1 cubic meter, yield of lumber from a log, When drying boards, z10kubiv is the way out, How many pallets come out of a workpiece cube?, How many uncut boards come out of one cube of round timber?, lumber yield calculator, the output of the board is not edged from the cubeShare this information on social networks to popularize the portal:

Forest sawing is a cycle of actions using a variety of technologies aimed at obtaining lumber from round timber suitable for further use in industry. The duration and labor intensity of the process depend on the chosen method of processing round timber, as well as the time of year.

Tools and equipment

Trunks and large branches are used for production. All material is divided into groups according to thickness and presence of bark. Often, timber processing enterprises have workshops near the harvesting site, in which machines for the initial processing of wood are installed.

Manual debarking of wood

Wood that has not passed the debarking stage can be used on floors or as ridge beams in the corresponding interior, or as a supporting device during construction.

Industrial debarking of forests

If another option for using the wood is planned, then sawing is carried out, resulting in the following segments:

- unedged and half-edged (rough material from which the bases of the floor, walls or ceiling are mounted);

- edged (intended for finishing flooring).

The cutting can be carried out by a mobile organization that has all the necessary tool.

Wood cutting map

Rational use of the material is ensured by compliance with the cutting map. This allows you to reduce costs due to waste, the percentage of which the card can significantly reduce. The tools and types of forest processing equipment used depend on the volume, desired quality and size of the finished lumber.

The most commonly used are a circular saw and various machines:

- circular due circular saw allows you to make precise cuts in various directions. Suitable for both professional and home use, copes well with round timber diameters above average;

- chainsaw;

- machines for clean bark removal;

- sawing on a band sawmill makes it possible to process dense logs; it is considered the most popular, since the yield gives quality material and a small amount of waste;

- disk machine: production of double-edged timber and unedged boards;

- a frame sawmill does not require a foundation, the technology using it allows you to install the equipment in close proximity to the felling site;

- fine meter processed universal machines, gives a way out quality building materials even from low-grade whips;

- sawing of round timber at a large woodworking enterprise should be carried out with the largest amount of lumber, differing from the rest in its special quality and precise dimensions. For this purpose, special lines are installed for sawing.

At the sawmill, timber and edged boards are obtained by cutting logs up to 7 m long and 15-80 cm in diameter along the longitudinal line. A circular saw has one or more blades and processes different diameter forests according to their quantity.

If you need to process a small amount of wood at home, you can use a regular chainsaw.

Cutting wood

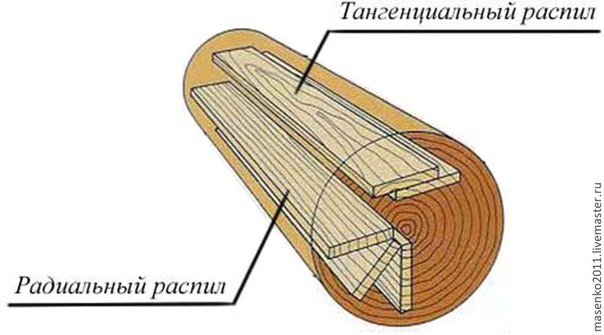

Before choosing a tool, you need to decide on the type of cut, focusing on the annual rings of the log. There are several types:

- radial (along the radius);

- tangential (the cut is parallel to one radius and touches the annual rings);

- the fibers are located parallel to the cutting being performed.

Among the cutting methods, the one that is most suitable for a particular case is selected:

- Waddle. Sawing wood in this way is carried out for deciduous trees with a small trunk thickness, it is considered simple processing. Output: unedged elements and slabs.

- If you have another forest processing machine, then it is possible to cut up to 65% of the material to produce edged boards of equal width. First, the double-edged timber and boards on the sides are cut, and then a certain amount of edged lumber is obtained from the timber.

- More specific methods are sector and segment sawing. The number of elements in the first method varies from 4 to 8, and depends on the thickness of the trunk. After dividing, elements are cut from each sector along a tangential or radial line. The second method begins with the timber coming out of the central part, and boards are cut from the side segments in a tangential direction.

- For individual cutting of wood, the circular method is suitable. It is based on turning the log along the longitudinal line by 90° after each sawn board. This allows you to monitor the quality of the wood and promptly remove affected areas of the trunk.

Manual work: using a chainsaw

For home cutting of several trunks, it is not advisable to purchase a tool whose cost is several times higher than the price finished products. If you have the necessary skill, then it is more efficient and cheaper to do all the necessary work with a conventional chainsaw or chain equipment powered by electricity. Of course, such work requires much more physical effort and time, but the cost of the issue is significantly reduced.

Work for garden plot requires pruning fruit trees, and it also becomes possible to additionally produce material for outbuildings without resorting to the services of specialists, so any thrifty owner will prefer to buy a chainsaw. Most often, coniferous wood is harvested for the home, and this tool does an excellent job of cutting it. Thanks to straight trunks, it is easier to mark cutting lines, which increases the speed of work. Professionals, by the way, most often use a chainsaw, since it is more powerful than an electric one and can be used anywhere, regardless of whether there are power sources at the cutting or cutting site.

To use a chainsaw to cut logs, you will need a device such as a saw attachment, as well as cutting guides and base-trunk fasteners. The frame-shaped attachment is attached to the tool so that it remains possible to adjust the distance between the chain and the frame itself. This is done to make it possible to produce finished lumber of different thicknesses. For the role of a guide, you can take either a profile of the required length, or an even wooden plank with sufficient rigidity. A special chain is selected for the tool, designed to cut the trunk lengthwise. Its difference from the others lies in the teeth sharpened at a certain angle.

Before you start work, you need to not only prepare all the necessary tools. Regardless of whether a woodworking machine is intended for processing a trunk or hand tool, the first thing you need to do is familiarize yourself with the cutting map. This is done in order to minimize the percentage of waste and increase the yield of useful products.

The first thing you need to worry about when longitudinal cut– uniform density of finished boards. To do this, a competent sawyer directs the tool from the east side of the log to the west, or in the opposite direction. This is explained by the higher density of round timber in its northern part than in the southern part.

Next, use a chainsaw to remove the slab from both sides so as to obtain a double-edged beam. It, in turn, is sawed in accordance with the cutting pattern chosen at the beginning of the work. The solution is an unedged board. If there is a certain percentage of defects in the trunk, then a circular cut is possible with the trunk turning at a right angle or 180°.

Quantity of finished material, cutting price

Exit useful material from coniferous and deciduous species differs in percentage. For lumber obtained from coniferous trees, the following indicators are characteristic:

- provided that the operation is carried out by a professional and a circular sawmill is used, the percentage of finished wood will be the highest (80-85%);

- the edged material produced by the machines averages 55-70%;

- When used with a chainsaw, an unedged board leaves up to 30% waste.

The figures are given without taking into account the finished culled timber, the amount of which can reach 30%. However, such material is used for products that allow certain defects.

Deciduous round timber produces 60% of the finished unedged timber and about 40% of the edged timber. This is explained by the initial curvature of the round timber. It is possible to increase the amount of products obtained: this will require forest processing machines of various types. A certain kind of device can increase the amount of lumber by 10-20%. For one cube of lumber you will need about 10 cubes of deciduous round timber. The cost of installing additional equipment will be recouped by the cost of the finished timber. Special lines provide greater volume, but their use is only advisable over a large area. The average price of sawing wood at a regular sawmill will be approximately 150-180 rubles per cubic meter of boards.

Sawing map

The sawing map is a calculation of the optimal amount of finished lumber from one log. You can calculate it yourself for each specific log diameter, or you can use a computer program that greatly facilitates the calculation, and the price of which is quite affordable.

Or the source could be a regular sawmill reference book. The result is a table that is taken as a basis. The sawmill attachment should always be oriented to its data in order to obtain more lumber of any type of wood.

To obtain a high percentage of lumber from round logs, several different technologies are used, including certain cycles of actions. The time required for sawing round timber and the labor intensity of the process varies, depending on the chosen processing method, the location of the work, and the season. Thus, some enterprises build workshops for the primary processing of raw materials near the timber harvesting site and save on this.

Not only trunks, but also large branches are processed. Roundwood logs are sorted by size and presence of bark. The trunks that have not been sorted are used later for rough work (manufacturing scaffolding etc.). When accepting raw materials from the supplier, not only the cubic capacity is checked, but also the presence of damage, rot, knots - such materials do not comply technical specifications. Defects in wood reduce the percentage of finished products at the output, and knots can damage equipment.

Before sawing, trunks are often debarked (bark is removed special machine) – this process is optional, but is considered economical:

- due to the absence of stuck pebbles and sand in the bark, the saw is protected from premature wear;

- the quality of the chip material improves;

- some enterprises do not accept slabs from unbarked logs for processing;

- the error in results when sorting wood using electronics is reduced.

Types of wood cutting

First of all, you need to decide on the type of cut - there are several of them. Tangential - the cut goes tangentially to the growth rings, the surface is obtained with patterns in the form of rings and arches. Boards obtained in this way are cheaper, but have high percentages of shrinkage and swelling.

Radial - a radial cut, perpendicular to the growth rings, the pattern is uniform, the yield of the board is small, but it is of higher quality and greater strength.

Rustic – carried out at any angle, defects, knots, sapwood, etc. are visible.

Cutting methods

For each specific case, a cutting method is selected.

Tumbling is the most economical, almost no waste, high percentage of finished timber. The output is unedged boards and two slabs.

With lumber - first you get a double-edged beam, unedged boards, and two slabs. Then the timber is sawn perpendicular to the cut into edged boards, along the edges two unedged boards and two slabs are obtained.

Sector - first, the log is sawn into 4–8 sectors, and then each of them into radial or tangential materials. Sometimes several unedged boards are cut in the center.

Break-up-segment - with this type of cutting, two or more unedged boards are cut in the center of the trunk, and edged one-sided boards are sawed from segments on the sides.

Beam-segment - similar to split-segment, only in the middle of the log a two-edged beam is cut, which is then sawn into edged boards. The yield of lumber is high.

Circular - after sawing off one or more unedged boards, the log is rotated 90 0 and the following boards are sawed off. This method is used when a large log is affected by heart rot in the center. With its help, healthy wood is separated from low-quality wood.

Aggregate - using milling tools and circular saws, along with high-quality lumber, the output is technological chips (instead of slabs and slats). Such complex forest processing allows for rational use of raw materials and labor costs. This results in waste-free production of finished lumber.

Necessary tool

The choice of tools depends on the quantity of planned finished products, their quality and product sizes. Most often, cutting is performed circular saw. On certain stages production requires the use of special machines.

The circular saw makes precise cuts in any direction, copes well with any size of log, and is suitable for professional and home use.

It is used for home use when it is necessary to prepare a small amount of lumber. It's easier to do more difficult jobs with a chainsaw than to buy expensive equipment. All you need for it is a special attachment, a barrel fastener and cutting guides.

Machines for removing bark. They are quite expensive, but with regular use in an enterprise where large volumes of work are performed, they quickly pay for themselves. They are not required to be used, but are desirable because they can provide a number of economic advantages and conveniences in the production process.

You will also need:

- Disc machine – for obtaining unedged output materials from the forest.

- The band sawmill produces high-quality lumber and a low percentage of waste.

- Frame sawmill – does not require a foundation and can be installed directly in logging sites.

- Universal machines are capable of producing high-quality material even from low-grade wood.

In enterprises with mass production to obtain ultra-precise and quality products entire complexes are installed modern equipment, and sawing of wood is carried out of any complexity.

Sawing technological map

To calculate the optimal percentage of obtaining finished lumber from logs, a forest sawing map is drawn up. These calculations can be done independently or using a special computer program. Such information can also be obtained in a regular reference book, which contains information on sawmilling operations.

The cutting map allows you to determine how many finished products will be produced and what percentage of waste will be recycled. From these data, you can determine the final cost of the product. The result may largely depend on the type of forest. There are some measures to increase the percentage of lumber yield.

The percentage of lumber at the output is ready-to-use, useful wood. Waste - raw material for obtaining MDF boards, chipboard, fibreboard. These volumes will depend on the diameter of the tree, the types of solid wood products being manufactured, and the sawing option.

Percentage of round timber

Accurate calculation of each cubic meter of wood - an expensive natural raw material - is important in every woodworking enterprise. Cubic meters of roundwood are calculated in several ways.

By volume of transport. Each type of transport has its own forest cubic capacity calculated and determined. For example, a carriage holds 70.5 cubic meters of round wood. Then there will be 22.5 cubic meters of it in three cars. This method of calculation speeds up the acceptance of raw materials, which is especially important when there is a large amount of incoming cargo. But there is a large error in the calculation results in this way.

Calculation based on the volume of one trunk. If the entire logging consists of timber of the same size, then by counting the volume of one, you can count them all and multiply by the cubic capacity of one. This method is more accurate, but requires a lot of time and the involvement of more workers to accept the cargo.

Automated systems with measuring frames. These measurements provide higher percentages of accuracy than those taken by humans. When logs pass through the measuring frame, all thickening and curvature of the trunk and even knots are taken into account. In this case, you can immediately sort the trunks.

A method of calculation by multiplying the volume by a coefficient. The height, width, and length of the stack are measured and multiplied by a coefficient. This calculation is fast, but with a low percentage of accuracy. It is used when it is necessary to urgently determine the number of cubic meters.

Dependence of the final yield percentage on sawing technology

To increase the yield of finished lumber, it is necessary to optimize the sawing process itself. This is especially true when working with workpieces that have curvature, damage or other flaws:

- First, you need to select and put into production only high-quality wood.

- Then select trunks with damage at the ends (rot, cracks) and trim these places.

- If there is a section of trunk with a rotten core, it must be removed and the remaining wood cut into lumber. They will be shorter, but of better quality.

- The circular cutting method is also suitable for obtaining high-quality boards.

- The yield percentage is higher when sawing timber with a larger diameter.

The yield also depends on the quality of the log, the type of wood, and the equipment used. New high-quality, well-tuned equipment allows you to process trunks with almost no losses.

The efficiency of timber cutting can be increased if special measures are taken in advance. To do this, you need to make accurate calculations using digital programs. If you do this manually, the percentage of output defects will be higher. It should be taken into account in advance that coniferous forest species produce a larger percentage of lumber output. Because their trunks are smooth, large, less susceptible to rotting and therefore almost free of defects. A large volume of deciduous trees is often discarded.

For rational use For wood, it is better to take short logs. But in domestic production, trunks with a length of 4 m or more are usually taken for sawing. Due to their curvature, the output results in a large percentage of rejects.

Edged board is one of the most common lumber in construction. It is used for outdoor work, during construction wooden houses, interior decoration, manufacturing wooden fences. The board is sawn from logs and additionally sawed along the edges. This gives the lumber not only presentation, but also preserves it from various pests. Typically the width edged boards twice its thickness.

The greatest demand in construction is for boards made from coniferous wood - spruce and pine, Siberian larch. For the production of furniture, more expensive and durable types of wood are used - oak, alder, ash.

The quality and cost of lumber depends on many characteristics: the type of wood, its moisture content, processing and sawing technology. Therefore, it is important to correctly calculate the yield of edged lumber in production.

depends on many factors: the specification, the grade of the board, the diameter of the saw log.

For example, from coniferous roundwood, the yield of edged lumber on band sawmills is usually 55 - 60%. On disk sawmills this percentage increases to 70-75%.

The yield of edged boards from round deciduous wood (aspen, birch, linden) is always very low for all types of sawmills. Approximately 35-40%. This is due to the curvature of hardwood logs. You can increase the percentage output only by setting additional equipment- multi-rip, edge-edging and slab machines. The yield, in this case, will increase by about 20%.

Generally? prices for lumber fluctuate greatly, and many lumber companies provide edged boards at a price significantly lower than the market price. However, before you buy lumber from such sellers, you need to think about what pitfalls may be hidden here. Often the cost of boards is reduced due to the low quality of lumber. Thus, it is most appropriate to purchase edged boards from those companies for which selling wood is not a new thing.

Similar materials

Edged boards are used in many industries, but most widely in construction industry. They are lumber that has an almost uniform (with some tolerances) cross-section along its entire length. That...

Grade 2 edged board has a beautiful texture natural wood and is the most commonly used material. It can be used to perform a wide variety of construction work. Price of edged board 2...

Before sawing round timber, it is necessary to calculate how much volume will remain for further exploitation, and how much material will be spent on recycling. This is important because it affects the final cost of the product. The amount of untrimmed wood produced will depend entirely on what type of wood is used. At the same time, there are certain measures to increase the yield of lumber after cutting.

What is the yield percentage and its dependence on the diameter of lumber

To understand this, it is necessary to unpack the concept itself. Roundwood lumber yield is everything useful tree after cutting. The rest is waste that is sent to further processing for the production of materials such as MDF, fiberboard, chipboard. It is worth understanding that the volume that will be obtained as a result of cutting wood is calculated for each individual diameter and selected cutting option.

It is worth understanding the question of why the parameter under consideration depends on the diameter of the forest. Everything here is extremely simple: the fewer cuts there are on the tree, the higher the volume value will be. Of course, a lot will also depend on the cutting technology and on the sequence in which the cutting was carried out. The correct sequence will be shown in Fig. 2. It should be understood that small lumber is obtained from small species of wood, and thick boards and beams are made from large timber. It is also worth considering the average diameters with approximate rates of volumetric flow rate:

- 14 – from 45 to 50%;

- 20 – about 52%;

- 25 – on average up to 57%;

- 34 – this is the diameter of timber timber, which differs in the most high value volume fraction equal to 66%;

- if the forest has a diameter of more than 40 cm, then there is a sharp decrease in the materials obtained.

Volume of waste after sawing

To finished products had a large percentage, everything should be calculated and prepared correctly. And the work process itself must be carried out in full accordance with technology. It is worth taking into account that a round forest of coniferous and deciduous trees will produce different yields of lumber from unedged boards in m3.

Pay attention! Conifers wood are considered the best option, due to the fact that they have a straight trunk and a relatively larger diameter. In addition, such wood is not as susceptible to decay, which leads to less waste.

When working with deciduous trees 2 processing methods are used:

- Using band sawmill at 375 or 363.

- In ruins. This technology involves cutting out a half-beam, which is subsequently passed through a multi-saw device.

In this case, the first method allows you to get approximately 40-50% of the output. But the collapse technique differs in a slightly larger volume - up to 70%. The disadvantage of this technology is that its costs are relatively high. When sawing round timber 3 m long, you can notice quite a high level marriage. However, the remaining wood will not be immediately useful due to the fact that it requires an additional processing process.