Icer

1931 0 0

March 14, 2017

Specialization: master in construction plasterboard structures, finishing works and styling floor coverings. Installation of door and window units, finishing of facades, installation of electrical, plumbing and heating - I can give detailed advice on all types of work.

Types of screws and their features

All fasteners that are used in the construction of plasterboard structures can be divided into three groups:

- Self-tapping screws for fastening plasterboard sheets (GKL) to a metal profile;

- Fasteners for mounting the material on a wooden frame;

- Screws for assembling a metal frame.

Let's look at each option separately.

Screws for attaching gypsum boards to a metal frame

This type of product has the following features:

- Frequent thread pitch. It ensures strong fixation of fasteners in a metal profile of small thickness. It is very important that the thread is uniform along the entire length, without defects or damage;

- Oxidized coating. To increase sustainability metal surface to corrosion, it is treated galvanic method. The color of the coating can vary from black to gray. This does not affect reliability, the main thing is that the entire surface is covered with a protective layer;

- Head for PH2 nozzle. This is the most common slot option, so choosing the right equipment for the job will not be difficult. The main advantage of this type of attachment is that it is well suited for both manual and automatic tightening;

- Sharp end. In order for a screw to screw well into drywall and quickly pierce a metal profile, it must have a sharp end. This is a very important nuance that you should always pay attention to;

Sometimes drywall is attached to a profile with a thickness of more than 1.2 mm. In this case, instead of sharp fasteners, a special version with a drill is used. But such a profile is extremely rare (I myself have encountered it only once in 15 years), so sharp self-tapping screws are most often used.

- Various lengths. Drywall can have different thicknesses. In addition, sometimes the material is laid in two layers, so fasteners of different lengths are used. Standard option for single-layer installation - 3.5x25 mm, if the material is installed in two layers, then 3.5x35 mm screws are used.

Instructions for installing drywall using this type of fastener look like this:

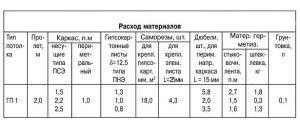

| Illustration | Description of the stage |

|

The sheet rests tightly against the surface. If this is easy to do on the walls, then on the ceiling you need to either use special device, as in the photo, or involve two assistants. They will hold the element until you securely fix it to the frame. |

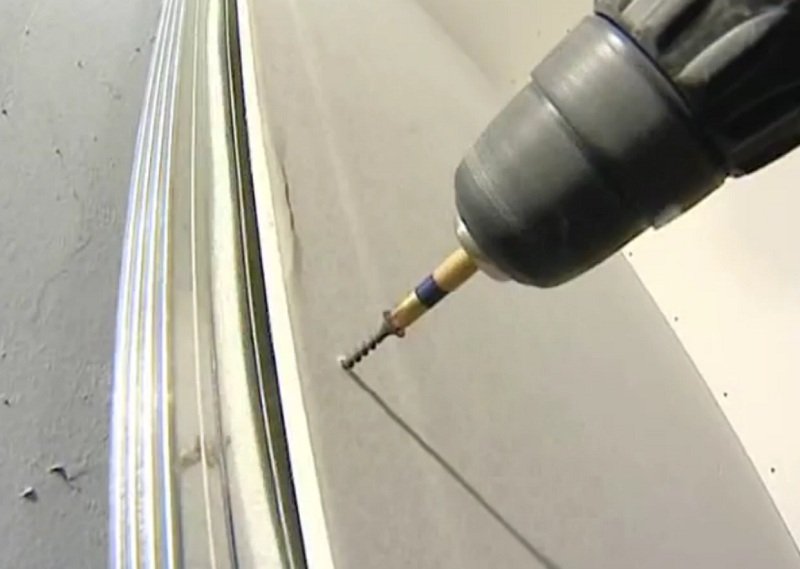

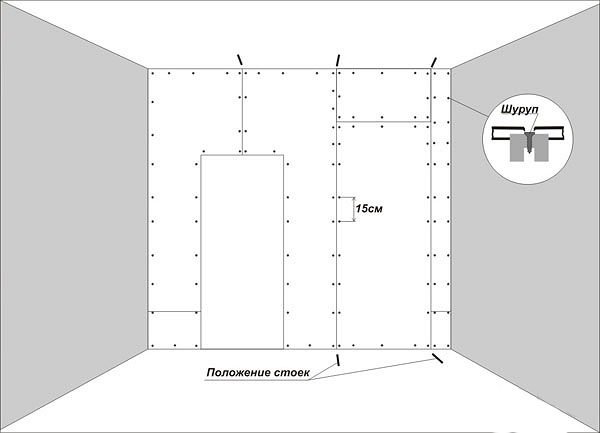

|

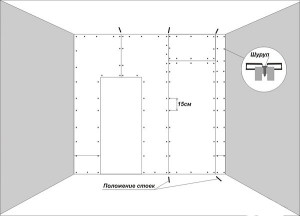

Fastening starts from the edges. The screws are spaced at least 15 mm from the end to avoid damaging the material. The fastener spacing is 15-20 cm. It is important to screw in the screws evenly so that they do not warp and the head does not become at an angle to the surface of the drywall.

|

|

The diagram shows the location of the fasteners along the edges. Two edges are fixed to each rack; pay special attention to the openings and the upper and lower parts of the structure. |

|

Difficult areas are secured especially carefully. All protrusions, bends, etc. are fastened according to the situation, if you see that the standard distance of 150 mm does not ensure reliability, then place the screws closer. The main thing is reliability. |

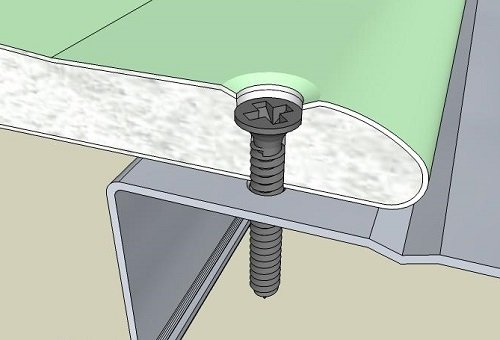

|

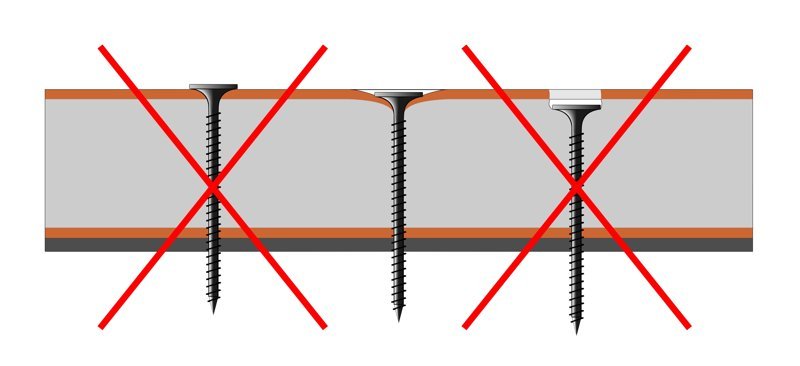

This is what it looks like correct location fasteners. The head is slightly recessed into the surface, this allows you to putty the fastening points and hide the screws during finishing. |

The consumption of fasteners per sheet measuring 1200x2500 mm is 70 pieces. In terms of square meter that's about 24 pieces. I advise you to purchase screws with a reserve; during the process they get lost, break, and there is almost always a small percentage of defects.

Screws for attaching drywall to a wooden frame

This type of product has the following features:

- Wide thread pitch. In order for the fastener to easily fit into the wood and stay firmly in it, the thread must be large. This is the simplest sign by which you can easily distinguish one type of fastener from another. There are only two standards, so it is impossible to confuse them;

- Oxidized coating;

- Head for PH2 nozzle;

- Sharp tip. Here the requirements are not as high as for profile screws. You can also screw fasteners that are not very sharp into wood, but the tips should not be too rounded. This complicates the twisting process;

- Big size range . The length of the screws can be from 16 to 152 mm. But for drywall, fasteners are used in the range from 25 to 51 mm. The choice of a specific option depends on the thickness of the sheets, the number of layers and the quality of the base. If the bars or board on which the drywall is attached are loose, then it is better to take longer fasteners to ensure high quality fastenings;

Let’s figure out what nuances need to be taken into account when doing the work yourself:

| Illustration | Description |

|

Can be sheathed frame structures . If you are building frame house, then you can attach drywall directly to the partition structures, having previously laid heat and sound insulating material in them. |

|

Wooden frame suitable for dry rooms. Unlike metal profile wooden blocks may become deformed due to changes in humidity. Therefore, they should not be used in bathrooms or other similar areas. |

|

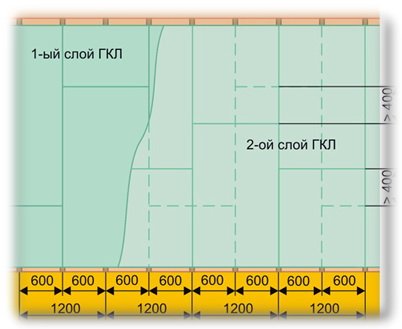

This is what the sheet fastening scheme looks like. Pay attention to the pitch of the screws along the edges and in the middle of the elements. An important nuance is also that transverse joints, if present, should be offset by half the height. This ensures maximum resistance to future cracking. |

|

When fastening in two layers, the sheets must be shifted in all directions. This is very important to ensure reliability. The diagram shows all the necessary data for both the frame and the installation of sheets. This correct option system that is worth implementing. |

|

This is what the correct mounting option looks like. You must clearly understand that the cap should not stick out above the surface or be recessed too deeply into it. To check the quality of fastening, run your hand over the drywall after fastening; you will immediately feel all the protruding caps; they need to be tightened. |

Screws for frame assembly

It is impossible to do without a strong frame a reliable wall or ceiling. Therefore, it is necessary to consider the fasteners for constructing the structure. Special screws are used, which among specialists are called bugs or seeds.

They have the following features:

- Specific Size. The thickness can be 3.5 or 3.9 mm, and the length can be from 9 to 11 mm. More is not needed for a thin-walled profile;

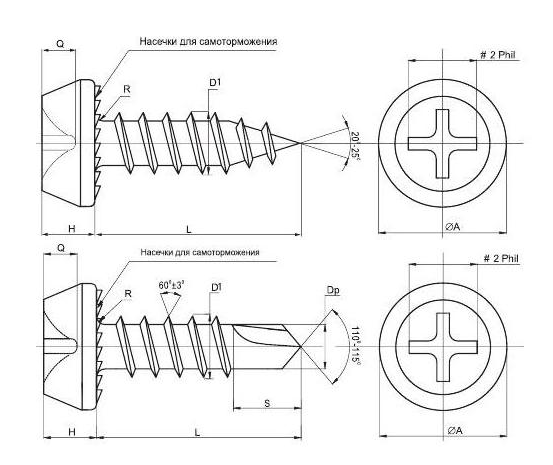

- Different types of tips. The first option is sharp self-tapping screws; they screw well into a profile up to 1 mm thick. The second option is a tip with a drill; this type of fastening is better suited for profiles with a thickness of 1 mm or more. It is not advisable to use it on thin elements, it scrolls big hole and holds up worse than sharp;

- Different types of coatings. Along with the already familiar black oxidized layer, screws can also have a galvanized surface. This type has a silver color and its performance is close to the first option. In my opinion, both solutions have the same quality, and the price is always the same;

- Presence of a press washer under the cap. The drawing above clearly shows that on the bottom of the head of such screws there are serrations applied counterclockwise. They allow you to securely fix the screw on the surface, preventing it from unscrewing;

- Standard spline. This fastener is screwed in with the same attachment as regular self-tapping screws - PH2. It's very convenient and practical, you don't need to stock up different types equipment to carry out the work.

Let's look at the most important aspects use of this type of screws:

| Illustration | Description |

|

Before fastening, the elements are carefully aligned. It is very important to determine the exact location of the profile and level it. Fastening is done from the side shown in the photo; each connection must have at least two self-tapping screws. |

|

When connecting the profile, one screw is screwed in on each side. It should be located approximately in the middle of the connector running inside the profile, this ensures maximum reliability. |

|

This is how they are held together corner connections . The screws must be placed diagonally to ensure rigidity and resistance to stress. Do not place the screws too close to each other. |

|

When attaching the profile, hold it. Until the self-tapping screw penetrates through both profiles, press it against outside. Otherwise, it may bend and connecting the structure will be much more difficult. The screwdriver should have high speeds, this will break through the profile much faster. |

|

When attaching suspensions, it is better to screw in two self-tapping screws. When connecting hangers and profiles, one fastening point on each side is often used. But this does not provide the required rigidity, so it is better to use two attachment points at each joint. |

|

Here is an example of how a self-tapping screw with a drill and a sharp tip is positioned. You don't need to be an expert to understand that the sharp version holds up much better, since it does not drill a hole, but punches through the material, bending it inward. |

Instead of self-tapping screws, you can use self-tapping screws with a press washer. They have a diameter of 4.2 mm, are coated with zinc, and the main difference between this option is the wide cap. The length may vary, but options of 13-16 mm are used. The biggest disadvantage of this solution is the price; they cost twice as much as standard bed bugs.

We figured out what screws to use to fasten drywall, now I’ll tell you how to choose quality option in the store. There are several main signs by which any master can choose reliable self-tapping screws:

- Thread quality. It should be the same along the entire length of the screw. The distance between the turns is uniform, they are even without defects or empty areas. Special attention Pay attention to the sharpness of the screws; they should prick when pressed lightly with your finger. If the tips are rounded, it means that the product was made on worn-out equipment;

- Coating uniformity. There should be no streaks, uncovered areas or other defects of this kind on the screws. All problems are visible to the eye; if the fastener differs in quality, it means that the technology was violated during its processing and the quality of the coating will be low;

- Neat slot for a screwdriver. Many times I encountered a situation where a screwdriver did not fit into the slot on the head due to a manufacturing defect. So check out a few items to make sure everything is ok. If the slot looks careless or there is an obvious defect, then it is better to look for products from another manufacturer;

- Marking. Famous manufacturers caps are marked; they can have one or 2-3 letters on them, indicating that the product belongs to a particular brand.

Conclusion

I am sure that you have no questions left about what screws you should use when installing drywall and how to choose them correctly. The video in this article will help you understand the topic even better, and if something is unclear, ask in the comments.

March 14, 2017If you want to express gratitude, add a clarification or objection, or ask the author something - add a comment or say thank you!

Plasterboard panels - popular finishing material. It can be used for different purposes. Particular attention must be paid to the system of fastening plasterboard structures to the surface. Self-tapping screws for drywall are selected depending on the location of the structure and the type of material. We will talk further about what types of fasteners there are and how to install them on gypsum boards.

Types and sizes

Self-tapping screws are common fasteners with a wide head and a screw-in rod. Their scope is wide, since they allow the material to be securely attached to the surface. They are made from different metals, mainly steel alloys. Thus, the metal perfectly resists corrosion and allows the profile to be installed in rooms with high humidity.

Strengthening compounds are also used to fasten plasterboard sheets. Dowels and drywall screws are galvanized, which allows them to be more resistant to impact external environment. A phosphate or oxide coating is applied over the fasteners, which gives them additional rigidity and durability.

For drywall there are special self-tapping screws with a flat head that are screwed in using dowels.

Self-tapping screws for drywall profiles come in several types:

- TN25 (3.5x25 mm). They are coated with a layer of anti-corrosion agent and used to fasten a metal profile. They screw in almost all the way to the base;

- TN 45 (3.5x45 mm). They are used to attach hangers to the frame base. They also attach perfectly to a wooden base and are suitable for finishing plasterboard in several layers;

- TEX 9.5 (3.5x9.5 mm). The design of the screws is similar to a drill. They can be used to screw into steel frame. The drill can pass through metal 3 mm wide. Thus, there is no need to prepare a hole for the fastener.

What screws are needed for profiles and drywall

Typically, special plasterboard screws are used for fastening, allowing the profile to be securely connected to the surface. They have a flat head and are screwed in using dowels.

When choosing fasteners, you need to pay attention to:

- Dimensions. For one layer of material, 2.5 cm fasteners are sufficient, and if a 2-layer structure is installed, then 3.5 cm screws are used.

- Thread type. There are screws with frequent and rare threads. For plasterboard sheets, it is better to use screws with a rare thread pitch, which will create a reliable fastening and will not harm the structure of the material.

- Form. It is better to use sharp screws as they are easier to screw into the material.

- Head. Flat head fasteners must be used. They secure the sheet more reliably and make the structure resistant to loads.

When purchasing tools for installing drywall, take the choice of screwdriver seriously. Good screwdriver will help you get your work done faster.

How to screw in self-tapping screws for gypsum boards

The fasteners should be screwed in with a special screwdriver. First you need to screw it in quickly, and then, when the drill reaches halfway, continue at minimum speed. It is necessary to constantly monitor the insertion depth so that the head of the fastener is not very deep, but does not protrude above the surface of the sheet. Self-tapping screws for drywall need to be screwed in at a distance of 20 to 50 cm, depending on the surface area. Before screwing in the fasteners, you need to make markings on the surface. If there is damage when screwing in, then you need to remove the screw and cover this place with putty. New element can only be screwed in at a distance of 4 - 7 cm from the previous one. After installing all the screws, go over them with a spatula and completely tighten those that cling.

When a person asks what kind of screws are needed for drywall, you can’t help but be surprised. After all, everything seems to be clear, and there are few varieties of them. But still, there are several interesting nuances, so we became interested in this issue and thus this article was born.

So, what kind of screws are needed for drywall:

Screw length

Since the cost of self-tapping screws depends on their size, it is better to know what length will be enough so as not to overpay. There is nothing wrong with a person trying not to throw extra money down the drain - the protruding part of the self-tapping screw behind the drywall will simply “hang” in the air and it will be of no use.

- Self-tapping screws for mounting sheets. Since gypsum boards are most often used with either a thickness of 12 mm (wall) and 9.5 mm (ceiling), then no more than 6-8 mm should be added to this value. It doesn’t cost less - the self-tapping screw becomes thinner closer to the edge, but there’s no point in purchasing more.

- Self-tapping screws for fastening profiles. 10 mm is quite enough - the steel thickness is only up to 1 mm. It would be possible to do less, but they don’t produce it, because you need to leave a few millimeters for the drill.

- Self-tapping screws for mounting hangers. If a dowel is used, then you need to proceed from its size. And if the suspension is attached to wooden surface, then a length of 20-25 mm will be quite sufficient.

We do not point out mandatory savings to you. Just pay attention, because it often happens that workers buy the material themselves and you may not always realize that you have been “cheated.” Knowing which screws are needed for drywall is also necessary to avoid excess material. After all, on average, one sheet of gypsum board measuring 2500*1200 takes up to 60 pieces of self-tapping screws - and this is only for drywall, and there are also hangers and profiles.

Knowing which self-tapping screws are best for fastening drywall will ensure that you don't risk damaging your drywall sheet and will ensure the strongest possible adhesion. It’s not difficult to understand the intricacies of choice, and we will help you with this!

1 Which screws to attach drywall to – the science of installation

The correct choice of self-tapping screws is dictated not only by the dry plaster itself, but also by the frame to which you will attach the drywall. If it is a metal frame, then most often 25 mm metal screws are used to fasten material 12.5 mm thick in one layer, with a profile thickness of no more than 0.7 mm. If there are two layers of drywall, then 35 mm products are used. To make the structure stronger, it is important to prevent the seams of the bottom and top layers from matching.

If the profile thickness exceeds 0.7 mm, special fasteners are used, which are similar to metal screws, but instead of a sharp end they have a drill, thanks to which they can easily penetrate even a 2.2 mm thick profile. Such screws are also called “bugs”. The base of their heads has many notches that prevent the possibility of self-unscrewing. The shape of the head of the “bugs” is hemispherical or semi-cylindrical, with a cross-shaped slot. What is good about these products is that when twisted, the metal profile itself does not deform.

TO wooden frame The sheets are secured with appropriate wood screws. For single-layer installation, they should reach a length of 32 mm, but if there are two layers, 45 mm products are used. The main difference between products intended for wood and for metal is a wider thread pitch and a larger protrusion in the first case, due to which they are better attached to wooden elements frame. It should be remembered that self-tapping screws are not interchangeable - wood products will not be able to hold drywall to metal frame, just like fasteners for metal will not cope with wood!

2 Self-tapping screws for drywall profiles - dimensions and features

Domestic and imported manufacturers of fasteners try to adhere to the same parameters when manufacturing them. Traditionally, metal screws have diameters of 3.5 mm, 3.9 mm, 4.2 mm and 4.8 mm, while their length ranges from 16 mm to 152 mm! The dimensions of the “wooden” products are almost the same. We have already figured out which screws to use for drywall. Do you need to know how to screw a self-tapping screw into drywall? We dare to assure you that this is far from an easy task! To get a smooth and durable coating that will stand the test of time, you should adhere to a special work technology.

In your work you will need a screwdriver with various attachments for different sizes fasteners, a Phillips screwdriver, and a small magnet or magnetic tape.

The latter is necessary for the convenience of holding the products when both hands are busy - all you need to do is attach several fasteners to the magnet in advance and unhook it at the right time, and one hand is enough for this. Drywall craftsmen also have special belts with pockets for products of different lengths, but it is not always easy to reach them, so in such situations a magnet is needed. Attaching drywall to the wall with self-tapping screws should begin with marks on dry plaster in the places of future holes. This should be done in advance, since this process is not only inconvenient, but also fraught with a chaotic arrangement of fasteners. Depending on the load on the material, the step can vary from 20 cm to 70 cm.

3 Fastening drywall to the wall with self-tapping screws: screwdriver or screwdriver?

Having put the self-tapping screw on the nozzle, attach it to the point you marked. At first, if you are using a screwdriver, screw it in at maximum speed, but when it enters halfway into the sheet, you need to reduce the speed to a minimum. When working with a screwdriver, the main thing is not to put too much pressure on the handle of the tool and tighten it smoothly. The most difficult thing is to screw in the self-tapping screw correctly at the last stage, when there is very little left. The force of the screwdriver will be enough to tear the cardboard, and in this case the fasteners will not be able to ensure a rigid connection of the sheet to the frame.

It is also impossible to under-tighten it - this can cause problems during further finishing, and again the strength of the entire structure is lost. In order not to test yourself for accuracy and reaction, purchase a high-quality screwdriver bit specifically for self-tapping screws, in which its own axis is ideally aligned with the axis of the fastener. The bit holds it firmly without threatening to deform the head. Before tightening products, check the manufacturer's information to find out the optimal tightening force that should be set on the tool.

In addition to the correct length and purpose, you need to choose fasteners with a countersunk horn-type head, since such a head does not tear the cladding, but presses the edges of the drywall into the hole. When screwed in, it should be pressed into the material to a depth of no less and no more than 1 mm, this is just enough to subsequently hide the traces of the fastener with a small layer of plaster or. It is very easy to identify under-tightened screws - take an even spatula and run its tip along the seams and places where they are screwed in, and even the slightest flaw will be found.

It is not always possible to tighten the self-tapping screw the first time. However, you should know that after unscrewing the fastener, you cannot screw it into the old hole. Inspect the self-tapping screw - perhaps it was the reason for the unsuccessful tightening due to threads or unevenness. A distance of at least 5 cm is required from the old hole, while at the site of the failed hole it should be. For reliable fastening, it is important that the screws enter the frame at an angle of 90° by at least one third. For metal fasteners this is 10 millimeters, for wood screws it is 20. It is also important to maintain the distance from the edge of the sheet of dry plaster, which should not be less than 1 cm.

When installing sheets of dry plaster in one layer, fasteners should be tightened at a distance of 25-35 cm from each other. If sheathing in two layers is used, then the pitch of the screws when installing the first layer can be doubled or even tripled, while for the top layer the pitch is still the same 25 cm. It is important that there are no foreign materials between the sheets and the frame, otherwise drywall will be deformed.

4 How many screws per sheet of drywall - calculation of fasteners

Self-tapping screws will come in handy in any case, but it is not always possible to buy consumables with a large margin. To correctly calculate the consumption of self-tapping screws per 1 m 2 of drywall, you need to take into account several parameters. One of them is size plasterboard sheet. Usually it is 1200*2500 mm, although there are also non-standard sheets of smaller sizes.

The fastening pitch is the second parameter that will affect the number of screws. Traditionally, drywall is installed with an average fastener pitch of 35 cm - this is enough to ensure the reliability and durability of the structure. The number of layers is another factor that can affect the weight of self-tapping screws purchased. Taking these factors into account, the number of fasteners can be calculated with the slightest deviation. With the parameters listed above, one sheet will require about 70 units, while two layers will cost 100 units.