- Facade cladding using boards made of natural wood

- Facade cladding using siding: work technology

- Tools and materials

- Final work

After frame house was built, its windows and doors were installed, and the walls were insulated, you can move on to the next stage of construction, which will be covering the surface of the walls. At this moment, every master faces the question of what is outside. There are several options: you can use a board, for example, clapboard, or vinyl siding, as well as facade vinyl panels or ventilated facades.

Wall panels for frame house There are two types: hollow panels and panels filled with insulation.

They often decide to sheathe the outside of a frame house using siding, guided by the fact that this material has a long service life, which exceeds that of boards made of natural wood.

Thus, siding can last for at least 40 years, and the shelf life of boards is only 20 years.

A frame house is often sheathed with siding panels also because, unlike natural wood, this material is not exposed to fungal putrefactive formations, in addition, it is quite resistant to exposure to the sun, which cannot be said about wood, which cracks over time from ultraviolet radiation. Siding panels do not require additional painting, and the color range of such panels is very diverse to suit the tastes of consumers. By selecting wood paneling for the home, it will need to be further processed, which involves sanding, processing with two layers of drying oil, and also painting oil paint, which is sometimes replaced by processing using a protective decorative varnish.

Siding also has disadvantages, including cost and additional components for installation. For siding panels you will need a corner and a connecting strip. But, despite the whole range of advantages and disadvantages, siding and wood are widely used in the process of wall cladding wooden houses.

Facade cladding using natural wood boards

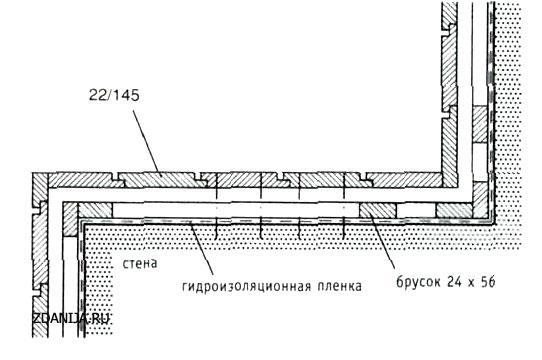

Construction of an insulated wall covered with façade boards: 1-vapor barrier; 2-outer wall; 3-thermal insulation; 4-hydrowind protection; 5-wood substructure; 6-front board.

Before starting the sheathing process, you need to make preparatory work. To do this, you should prepare a board - lining, the humidity of which should not exceed 10-15 percent. If the moisture content of the wood is higher than normal when the walls are finished, further shrinkage will begin, which will cause a change in the density of the joints of adjacent boards, the formation of cracks, which will negatively affect the appearance of the entire building.

It is recommended to sheathe the outside of a frame house at the end of August; work can be carried out until the beginning of September, because the effect of the sun on the finishing material does not have such high intensity, which cannot be said about the summer months. Thus, the purchase of boards for cladding must be made in advance, no later than the end of May or the first half of June. This is due to the fact that to dry the wood before required humidity under natural conditions it will take at least two months.

The next stage will be the process. In this case, work should start from the bottom. The panel should be positioned with the groove upward, but the tenon should be directed downward, strengthening the starting (first) board. The horizontality of the board must be measured with a building level.

The second and subsequent boards should be reinforced in this way: the groove should be inserted into the tenon. Using a mallet, hit the board from above several times; this must be done carefully so that the wall of the lining groove is not damaged. This procedure is necessary so that the tenon fits into the groove as tightly as possible. The board should be reinforced with two nails along the edges of the panel, while stepping back a centimeter from the edge of the board. The length of the panel should be reinforced with nails in increments of no more than 50 cm.

After completion, the boards should be reinforced from the outside at the corners of the building in a vertical position: one board is fixed overlapping the other so that the panels form a corner. Using the same principle, it is necessary to install platbands on window openings.

You can sheathe the pediment by strengthening the boards vertically or horizontally as desired. You should be guided by the same principle when connecting boards as when cladding the outside of a house. After completing the planking, you need to quickly coat the surface with paint.

The next step in the work will be preparing the surface for painting. In order for the surface to be smooth after painting, you should use grinding machine subject the base to treatment, the machine must be refueled sandpaper, the grain gradation of which can vary between 25-120, a grain of 40 can be used as the optimal option.

If you plan to paint the facade of the house with oil paint, you will first need to apply two layers of drying oil to the surface of the cladding, and after drying, you can begin painting the facade. The surface is painted with a wide brush; a roller or spray gun can be used.

Return to contents

Facade cladding using siding: work technology

Siding is a panel that consists of paired boards like lining. Such products have a profile groove with a tenon and are designed to ensure fixation of adjacent panels.

The panel has a perforated edge with slots designed for fastening the panel using screws or nails. Bottom part The panel has a hole that is designed to drain condensate in the hollow space between the wall of the house and the panels.

Return to contents

Tools and materials

- siding;

- connecting strip;

- corner;

- building level;

- mallet.

Sheathing a frame house with siding can be done using a connecting strip, but if you want to save money, you may prefer a different method of connecting panels - overlapping.

The first step, if you decide to sheathe a frame house, will be preparatory work. Fastening products to the wall surface can be done in several ways. The panels can be mounted directly on the walls of the house or on a frame, the material for which can be aluminum. As an alternative, you can choose to install the panels on wooden blocks fastened to the walls in advance. The latter option is able to provide excellent ventilation of the space between the walls of the house and the cladding, unlike the first option.

Covering a frame house with siding, which will be strengthened on wooden blocks, instead of an aluminum-based frame will save up to 30 percent of money.

The first thing to do in this case is to strengthen the wooden blocks around the perimeter of the walls. The step between the bars should be no more than 50 cm. The bars may have different cross-sections. They need to be strengthened in a vertical position, fixing them with nails, the length of which varies between 40-50 mm.

The frame house should be protected at the corners with a vinyl corner, which will perform a decorative function and act as corner connection panels.

When the bars are strengthened, the house can begin to be sheathed. A starting strip is installed on the lower level of the sheathing, using a level to check that its position is horizontal. Only after you make sure that the horizontal of the starting bar has no deviations, you can strengthen it with self-tapping screws to the racks. This will need to be done around the perimeter of the house.

The frame house should be covered with panels, which should begin to be strengthened from the far corner of the building; this will make it possible to make the seams on the front side of the building invisible when joining the products with an overlap.

One end of the product is inserted into the groove of the corner, and then it is necessary to insert the profile tenon into the groove of the first plank. Such a connection has its own name - a lock; if it is performed correctly, the master, when inserting a groove into a tenon, should hear a characteristic click, meaning that the connection has occurred.

The perforated edge of the panel has special slots, through which the panel is fastened to the wall surface using self-tapping screws. After the first panel has been secured to the beam, you can begin to attach the second panel, using the principle of overlap onto the previously installed panel.

The outside of the house is sheathed, starting with the installation of the 1st, bottom row, moving along the perimeter of the house, after which you can begin installing the second and subsequent rows.

The outside of the house along the pediment is sheathed in the same order as when installing panels on the surface of the walls, however, in the process of sheathing the pediment there is no need to use a connecting corner.

A frame house is essentially a wooden house. However, thanks to the universal design, facade finishing options frame building can be very diverse. Private developers, like construction organizations, choose the most different options facade of a frame house: siding, brickwork and even a “wet” facade.

Let's consider the main options for cladding a house built using frame technology.

Facade of a frame house: we use vinyl siding

First of all, it should be noted that when covering a frame house, based on the climatic conditions of our homeland, the facade should be made ventilated. In this case, the siding will be attached to a counter-lattice installed on top.

First of all, it should be noted that when covering a frame house, based on the climatic conditions of our homeland, the facade should be made ventilated. In this case, the siding will be attached to a counter-lattice installed on top.

In Canada itself, where frame technology came to us, a ventilated façade is usually not required, but in Russia the climate is somewhat different.

Therefore, if the cladding of the facade of a house is done using vinyl siding, it is recommended to install a ventilated facade

Swedish-Finnish version of cladding using painted facade boards

Exterior finishing frame house can be made using facade boards or This option for finishing the facade of a frame house is quite popular in Scandinavian countries, where great value pay attention to the naturalness and environmental friendliness of the material.

Exterior finishing frame house can be made using facade boards or This option for finishing the facade of a frame house is quite popular in Scandinavian countries, where great value pay attention to the naturalness and environmental friendliness of the material.

The facade board, as a rule, has one part planed and the other sanded.

The polished outer (facade) side is left for better than that so that the paint is absorbed better.

Algorithm for design work frame houses the façade board will be as follows:

- The surface of the façade board is sanded.

- A layer of primer is applied to the entire surface of the board, like all wooden building materials used in building a house.

Important! Primer coating must be done within the first two days after sanding, while the pores of the wood are open.

- Next, the facade board is covered on all sides with a layer of paint.

- The board is attached to the facade of the house with a gap of about 2 mm.

- The decorated facade is covered with another layer of paint.

Subject to technology and use quality materials the façade board can retain its original appearance and not require additional painting within 9-10 years

Subject to technology and use quality materials the façade board can retain its original appearance and not require additional painting within 9-10 years

The wooden facade of a frame house should also be made, otherwise the solid elements will begin to rot and collapse.

Sometimes, instead of a facade board, finishing a frame house is done using edged boards or. Regardless of the type of wooden elements used, the algorithm for facing work will remain unchanged.

Facade of a frame house: we use fiber cement siding

- This is a fairly strong and durable material for cladding facades, reminiscent of ceramics to the touch.

It has a well-fixed colored layer, which is applied to the surface of the finishing material in the factory, so it does not fade for quite a long time.

At first glance, it is an excellent material for finishing the facade of a house. However, there are significant disadvantages:

Wet facade on a frame house

Wet façade finishing

The frame can be made using clinker tiles or. In this case, the “pie” of the wall will consist of oriented strand board attached to the frame posts, on which it is installed with a special fastener.

The resulting " wet facade"is needed, first of all, so that there is a basis for external decoration.

It is quite possible to make a wet facade of a frame house with your own hands. Used this technology when insulating a house with polystyrene foam, since fastening sheathing materials directly to foam plastic boards is impossible.

It is quite possible to make a wet facade of a frame house with your own hands. Used this technology when insulating a house with polystyrene foam, since fastening sheathing materials directly to foam plastic boards is impossible.

Plastering the facade of a frame house

If it is necessary to perform a “wet facade”, then the progress of work will be exactly the same as described above. Only a layer of plaster should be applied to the outer reinforcing layer, and not clinker tiles or artificial stone.

Plaster can also be applied to the facade of a house covered with cement-bonded particle board.

Brickwork as an option for finishing the facade of a frame house

Methods for finishing the facade of a frame house also include the option of cladding. Most often, “hollow” lightweight bricks are used, but sometimes “solid” bricks are also used.

Use of DSP in facade finishing

DSP boards for the facade of a frame house- enough comfortable material in finishing. This building material consists of a mixture of cement and wood. Due to the fact that the basis of the slab is still cement mortar, it practically burns, and is also resistant to moisture. The slab gains additional protection from moisture if it is soaked in drying oil.

Example of slab finishing

A significant disadvantage of DSPs is their heavy weight, and they are also quite difficult to cut. To attach the plates, you first need to drill holes. Accordingly, in this case, finishing the facade can hardly be called an easy task.

Facade materials: metal siding

Today you can also find an option when finishing a frame house is done. This option is also quite appropriate and the finishing is even cheaper than using vinyl siding.

Today you can also find an option when finishing a frame house is done. This option is also quite appropriate and the finishing is even cheaper than using vinyl siding.

The main advantages of using metal siding:

- it's a pretty durable material

- it is easy to install,

- the work can be carried out in a short period of time with your own hands.

However, metal alloy siding also has a number of disadvantages, associated primarily with the material itself from which it is made. The metal can corrode and the coating can be scratched; in addition, metal siding shields and heats up.

When installing, be sure to provide a ventilation gap.

Available on the market various colors metal siding

External facade of a smartside frame house

Smartside based on OSB boards – new material on the Russian market. Attached to the facade with ventilation gap.

Smartside based on OSB boards – new material on the Russian market. Attached to the facade with ventilation gap.

Its main advantage is that only one of its four sides needs painting. Acrylic paint is used for coating, which is applied in two layers. The joints are sealed acrylic sealant.

New smartside finish

In addition, manufacturers claim that this is a very durable material, and its service life is at least 50 years.

Of course, this is not a natural material, unlike the same wooden board.

Thus, developers can choose from a variety of options for covering the façade of a frame house.

The most important thing is to follow technology.

A variety of materials can be used for finishing the facades of frame houses.

Exterior finishing of a frame house - not an easy task, mainly due to the variety of facade finishing materials.

Exterior finishing of a frame house. Which material to choose?

________________________________________________________________________

Frame house — wooden house. Finishing a frame house- the matter is quite interesting.

Due to the versatility of its design, the facade of a frame house can be anything: from wood to a “wet facade” and even real brick. The exterior decoration of a frame house can be almost anything depending on the wishes and financial capabilities of the person.

In this article we will look not only how to choose a facade for a frame house, but also what it should be pie wall frame for high-quality execution of a particular facade.

1. The facade of a frame house made of vinyl siding.

Vinyl siding how exterior finishing of frame house installed quite often, this is probably the most popular and affordable option. This budget option and it looks quite tolerable. I decorated my own house with it, albeit vertically, I liked it better as it was quite unusual option— you’ve probably already seen the photo in other posts.

If you want to buy vinyl siding in Nizhny Novgorod with a 25% discount, call 8-920-022-18-11

Vinyl siding façade pies:

A. Ventilated

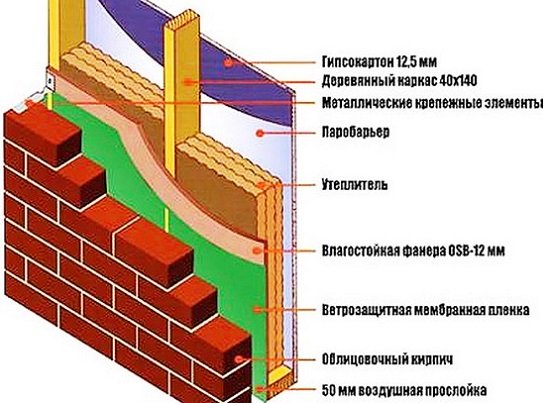

Interior finishing (often gypsum plasterboard) - vapor barrier film - frame with insulation - OSB-3 - hydro-windproof membrane - counter-lattice 50x25 (counter, because it runs parallel to the studs, and not perpendicular to the sheathing) - siding.

It should be clarified that in Canada itself, judging by the reviews of construction specialists, they almost never do this, but in Russia the climate is slightly different, so it is recommended to make siding with a ventilated facade for insurance.

B. Non-ventilated(Canadian version).

Interior finishing (often gypsum plasterboard) - vapor barrier film - frame with insulation - OSB-3 - hydro-windproof membrane - siding.

Siding installation:

The price is from 350 rubles per sq.m. for the most budget siding, but with more or less normal siding, all 500 rubles per sq.m. will come out.

2. Facade of a frame house made of painted facade boards (Swedish-Finnish version)

Typically in Scandinavia, the exterior finishing of a frame house is high-quality wooden boards or imitation timber good quality. Moreover, the front side of the board should be with a pile for better absorption of paint, and all other parts should be planed. Such exterior decoration The frame looks very decent, although the installation of such a board takes quite a long time.

There are several important subtleties with wooden board for the facade and finishing of a frame house:

— Needed grinding one side (as I already said). After that, you need to apply a primer to the entire board during the first two days, while the pores of the wood are open.

- After primers, before attaching the board to the facade, you need to paint it on all sides in one layer.

— We fasten the board to the facade, 2 nails 60 mm (galvanized) into each lathing through the board (or flush if you want to hide the nails)

— The gap between the boards should be about 2mm (nail)

— Apply 2 more layers of paint.

If everything is done exactly according to the technology, such a board can stand without additional painting according to 8-12 years(only high-quality paint is needed, for example, Nordica Eco 3330, Tikkurila or Teknos).

Wooden facades on a frame house They are almost always ventilated, otherwise they will rot.

That's why frame house facade pie with imitation timber or facade board it usually looks like this:

Interior finishing (gypsum plasterboard or lining) - vapor barrier film - frame with insulation - OSB-3 (the Finns install soft fiberboard instead and then do not install a membrane) - waterproof and windproof membrane - counter-lattice 50x25 - façade board.

In the case of a vertical board on the facade, after the counter-lattice it also goes on top horizontal lathing approximately the same cross section.

In the Russian version wooden facade

how to finish a frame house, imitation timber is often replaced with a regular one edged board or lining. This doesn’t change anything fundamentally, except that the lining is often installed in a “herringbone” pattern, like this:

There are also several options for wooden vertical boards on the facade “with a strip.”

Pie:

Cons: flammability, need to be repainted after a certain number of years.

The price turns out to be about 650 rubles per sq.m.— (price for 2017) with your own hands (with 3 layers of paint and a primer not made by yourself).

3. Finishing the facade of a frame house with fiber cement siding

One of the most famous - fiber cement siding Eternit. Feels like ceramic tiles. There is also Latonit, it is cheaper, but not as high quality. Exterior finishing of frame houses from Eternite looks rich.

Pros: durable, durable (longevity is promised to be about 30 years). It is painted in the factory, so it does not fade for decades.

Cons: high price, non-trivial installation (150 page instructions), difficult to do it yourself if you don’t have experience yet. Misunderstandings with additional elements. Corners are often sealed with metal or wood.

Per sq.m.= 1000-1500 rubles

4. Facade of a frame house made of clinker tiles or artificial stone using the “wet facade” system

Exterior finishing of a frame house according to the “wet facade” system requires high level training and skills. But to put it briefly:

Attach OSB-3 to the posts of the frame house. Attach 50-100 mm polystyrene foam to it (it’s better to use a special fastener rather than glue it). Then you make the first reinforcing layer, screws and clamping bushings, the second base reinforcing layer, and then attach clinker tiles or artificial stone weighing up to 44 kg/m2 to flexible glue.

This results in a so-called “wet façade”. A wet façade is needed so that there is something to attach the finishing to; it is not recommended to attach it directly to foam plastic.

Price 500-800 rub/m2, but for the work another 1200 rubles/m2.

To my house = with my own hands 150 thousand rubles, strangers 250 thousand rubles.

5. Plaster facade of a frame house

5.1. According to the “wet facade” system

Everything is the same as in the previous paragraph, only instead of tiles or stone there is paint.

Components of this façade:

— Baumit KlebeSpachtel glue

— Valmirovskaya façade mesh

— Baumit UniversalGrund

— Baumit SilikonPutz plaster coat 2mm

— Foam plastic

5.2. Plaster facade using DSP

For this option use cement bonded particle board followed by a joke.

Layers by DSP: primer - Knauf Sevener on fiberglass mesh - primer - Knauf Diamant

Knauf Diamant is already painted in white. No paint needed.

6. Brick facade in a frame house. Really?

Brick facades have also recently begun to be actively used in the finishing of a frame house. When cladding frame houses, you can use both “solid” and “hollow” bricks.

Attached brick to frame wall

done like this:

Read more about brickwork as a facade of a frame house and (search the page for the word “brick”).

7. Facade of a frame house made of fiber board under half-timbering

- a slab made of cement (most of it) and wood. It doesn't burn. It is practically not afraid of moisture (especially if you soak it in drying oil).

Among the disadvantages of DSP: the slabs are very heavy, and it is also very difficult to cut them + dust flies a lot from this. In addition, you can’t just nail it down; you need to drill holes first. Also, according to eyewitnesses, the DSP in the frame often cracks, so it is better to close the cracks wooden planks“under the half-timbered roof.”

But many people simply install DSP and paint water-based paint. And it seems like nothing bad happens.

Price per sq.m.= 215 rubles.

8. Finishing the facade of a frame house with metal siding

I saw several people on the forum who decorated their house metal siding and very satisfied. Metal as an exterior finish for a frame is still rare. The price is cheaper than vinyl, because... it does not require almost any additional elements, and for vinyl additional elements make up 50% of the cost.

If you want to buy metal siding in Nizhny Novgorod with a 25% discount, call me at 8-920-022-18-11

The benefits of metal siding: strength, ease of fastening, speed of operation

Cons: shields, aesthetics are not for everyone, can be subject to corrosion, easily scratched, overheats, condensation may form.

Must be installed with ventilation gap in the facade, like regular siding.

Price per sq.m.= 500 rubles

9. Finishing LP Smart Side siding panels based on OSB.

The material is new for Russia and is made on the basis of OSB-4. Some praise him, some criticize him. In terms of price, it is midway between regular siding and fiber cement. You can read reviews and opinions about it.

It is known that the cake needs a ventilation gap for it.

Video comparing its strength with the strength of fiber cement siding

Plus Smartside is that you only need to paint one side of the siding, and not 4 sides, as is the case with boards. They paint acrylic paint, in two layers. The joints need to be coated with acrylic sealant (A la Titan for siding).

Another plus is durability: they promise 50 years.

Cons The problem is that smartside is 2-3 times thinner than a wooden board and is not natural.

Price approx. 1100 rubles per sq.m.

Price for my house = 180 thousand rubles.

10. FSF plywood painted to look like half-timbered timber on a frame house

FSF plywood is attached to the frame and painted with 3 layers (primer + 2 layers of topcoat). Inner side covered with one layer of soil.

But estimate for the facade frame house in the photo:

Coniferous plywood FSF 9 mm, 1220x2440 mm, grade 2/3, NSh - 56 pcs - 35,784.00

Tikkurila Pika-Teho paint, white, matte, - 18 liters - 9,908.00

Primer composition Tikkurila Valtti Phyuste - 18 liters - 7,508.00

Galvanized self-tapping screws 4x50 3 kg - 615

Paint brush 1 pc – 90.00

Sealant gun 1 pc – 106.00

Frost-resistant silicone sealant 5 pcs – 540.00

Total 54,006.00

Price per sq.m. it turns out to be only about 300 rub.

11. Finishing the frame with shingles (shingles).

Original, beautiful and very expensive. Price approx. 1200 rubles per sq.m.

It is done with a ventilation gap. You also need to make a gap between the shingles itself.

Forum thread about larch shingles.

Surely, these are not all possible facades for a frame house. Add your options in the comments!

P.S. If you find a mistake, write it in the comments, I will correct it.

How the site can help you

1. Make you convenient and understandable (or buy finished project frame house).

4. Bring it to you from Belarus

5. 1. Consult on any issue of frame house construction.

HAVE YOU DECIDED TO THINK ABOUT FINISHING WORKS IN ADVANCE?

Let's do the finishing

your frame house

Start of finishing work

Finishing a frame house includes creating an aesthetic appearance and furnishing interior spaces. Your home will have its own unique exterior and become comfortable to live in. You can start finishing the frame house immediately after finishing construction work and in the very near future you will enjoy country life. If it is not possible to immediately begin finishing the finished house, then you can begin finishing work after some time has passed. A house using 3D frame technology will stand quietly for many seasons without external or internal finishing due to its technological features and high-quality materials.

Finishing the facade of a frame house

Frame technology differs favorably from other technologies in that the house can be given absolutely any appearance. Correct exterior design allows you to create the image of a classic mansion, a cozy cottage or an original modern house. Thanks to huge selection finishing materials and using proven technologies, we will bring to life the most original ideas. Only necessary from a wide variety possible options choose the one suitable for you. This can be done at the stage of designing a house. Based on your preferences and architectural style at home, we will help you choose optimal options exterior decoration of your future home.

Choose the exterior finish for your future home

Technological features of facade work

PLASTER “WET FACADE”

AND ARTIFICIAL STONE

The construction of facades of this type is considered to be an innovative construction method. The principle of construction of this facade is multi-layered, where each layer performs its own function. External finishing of the house with “wet facade” plaster and stone demonstrates its outstanding qualities only in case of strict compliance with the requirements of the work. This type finishing is carried out on adhesive based using various solutions. That's why facade works are produced in warm time year from May to September at an average daily temperature of not lower than +5 ºС.

WARNING PANELS,

IMITATION BEAM AND SIDING

Hanging systems are the most common finishing method country house. They, as a rule, have tongue-and-groove fastenings, which allows wet processes quickly complete high-quality façade finishing. This type of finishing does not require additional preparation external walls. Under the base, a lathing is usually used metal profiles or wooden blocks. Installation mounted systems possible to implement all year round, although there are temperature restrictions down to - 15 ºС. Filling the seams between the panels and painting the wood is done only at above-zero temperatures.

Interior decoration of a frame house

Interior decoration of a house using 3D frame technology is not a labor-intensive and time-consuming process. During construction, all necessary work is already included in the basic package, after which your house is almost ready for finishing. The electrics have already been installed, heating, ventilation, sewerage, cold and hot water supply have been installed, and plywood has been laid on the floor. There is no need to groove and plaster walls, lay communications, or screed the floor. We have minimized raw processes that inevitably arise when finishing. Immediately after the construction of the house is completed, you can begin to implement the design project, and we will help you with this.

Stages of interior finishing work

FIRST STAGE

INTERIOR FINISHING OF THE HOUSE

The interior decoration of a frame house can be done at any time of the year. If you are planning to decorate your house in autumn-winter period, then it is necessary to take into account that high-quality finishing work is only possible in a heated and dried house. In this case interior decoration better to start with technical room. After the readiness of those. premises, where it is located and put into operation heating equipment. Two to three weeks after starting the heating, you can begin finishing work in the house and not worry about the quality of the interior finishing.

SECOND STAGE

INTERIOR FINISHING OF THE HOUSE

If you are planning to decorate with wood, then it must be pre-treated and only then installed. If your design involves plaster or wallpaper, then the walls should be covered with gypsum board. It is better to make suspended or suspended ceilings. The floors in the rooms are already leveled with plywood, so laminate or other covering is immediately laid on them. The walls of the bathrooms are already lined with moisture-resistant gypsum fiber board; you can immediately glue the tiles. GVL has been laid on the floors of the bathrooms and is being done coating waterproofing and tiles are also laid.

THIRD STAGE

INTERIOR FINISHING OF THE HOUSE

One of the last stages finishing works is wallpapering and applying other finishing coatings. After this they are mounted electrical sockets and switches, lamps are hung. To the san. nodes house plumbing equipment, connect water supply and sewerage. Installed in openings interior doors. After the floors and walls are ready in the house, it is installed interfloor staircase and baseboards. Now you can bring in furniture, have a cat and enjoy country life in your new cozy home by technology

3D frame.

YOU WILL ALWAYS ADMIRE YOUR UNIQUE HOME,

After all, NOBODY WILL HAVE A BETTER AND MORE BEAUTIFUL HOUSE NEAR YOU

Times when wood was considered warm material, have sunk into oblivion. To prevent heat transfer through wooden wall its thickness must be at least 530 mm. For middle zone Russia. Frames individual houses in our country they are made mainly from wood, and sometimes they are used metal structures, which makes the problem even worse.

Therefore, the exterior decoration of a frame house, in addition to being purely aesthetic, often performs an important technological function - it thermally insulates the wood (or metal) of the frame, which itself serves as a cold bridge. Of course, in this article we will also consider finishing options that ignore this fact, but we have no right not to mention it.

What is the exterior of a frame house finished with?

There are no special restrictions on the exterior finishing of a frame house; there are some features of the use of one or another type, which we will inform you about. Frame houses are faced with:

- brick;

- tree;

- vinyl siding;

- thermal panels;

with the installation of a “wet facade” system,

- plastered;

- paint;

- polymer coatings are applied.

Deciding on one form or another exterior finishing home, you must take it at the stage of its design, since some of them begin already at the stage of laying the foundation.

Cladding a frame house with bricks

If you have decided that your frame house should appear brick in appearance, then one of the options is to line it with natural brick. The main requirement in this case is the presence of a gap of 30 - 50 mm between the wall of the house and inside brickwork and ventilation holes, providing air circulation in this gap.

If this is not done, then inner surface In the cold season of a brick, moisture will inevitably condense, which will ultimately lead to its accelerated destruction. It will also not spare the outer enclosing material of the frame itself, which is most often OSB or plywood.

Naturally, both the width and the bearing capacity of the foundation with this type of finishing are adjusted upward. Actually there are two different systems house building and when combining them, you should try to avoid rigid connections between the frame, which does not shrink, and the brick shell, which shrinks throughout the year. The consequences can be dire.

This can be disguised by a lowered roof overhang that is not connected to brickwork. Also, either postpone for a while the manufacture of external window and door slopes, or do not make a rigid connection with the masonry. These can be metal or plastic corners.

Cladding a frame house with wood

Proper cladding with wooden moldings, such as a block house, false beams, etc., will give your home a stylish appearance. Using them can also eliminate the external cladding of OSB, plywood or other board material from the wall pie.

Well-dried and treated with the necessary impregnations, textured wooden beam can be directly attached to the frame posts of the house from the inside, before laying the insulation layer, as well as with clamps or through self-tapping screws - after it. Keeping in mind that wood can be a bridge of cold, we can recommend such fastening in the case of erecting a double frame, with the posts shifted relative to each other.

Also frame finishing wooden elements can be done over a lathing with a ventilation gap. It is important to remember that such a facade of your home will require periodic maintenance, which consists of timely treatment with coloring and impregnation materials. And, of course, the tree will crack somewhere, somewhere on sunny side the gap at the joints will increase. You just need to be prepared for this when choosing this option for exterior decoration of your home.

Recently appeared in a large assortment composite materials, imitating the structure of wood, are completely devoid of these shortcomings, but those who are willing to shell out a fairly large sum for their purchase can be convinced of this.

Exterior siding

This is the simplest option for finishing a frame house. If you have OSB or plywood outside your house, you can simply attach strips of vinyl or card basement siding on them. These materials practically do not change their geometry when exposed to heat and cold; the siding itself will protect them from water, so you don’t have to look for complicated and expensive ways to make your home beautiful. They also hold screws well.

The choice of a column-beam version of the frame allows you not to use external cladding OSB or other materials, and attach the siding directly to the frame posts.

If you want to thermally insulate the wood of the frame, then attach the siding to external vertical slats screwed to the horizontal sheathing with a shift from the main beams of the frame and filling the gap between them with insulation.

At the same time, it is important not to forget that on the outside of the wall there should be insulation with greater thermal insulation capacity, or the same as that used in the wall pie, in order to avoid moisture condensation at the boundary of the materials.

This type of finishing makes the house even more repairable than one assembled using technology, finished with other types of materials.

In addition to plastic siding, you can use metal siding, but more often it is installed on non-residential buildings.

Finishing a frame house with thermal panels

Thermal panels are different. By dimensions, by materials, by type and method of fastening. But they have one thing in common: the presence of a layer of insulation and an outer finishing layer. The insulation can be polyurethane foam, polystyrene foam, or dense basalt.

Outside there may be: clinker tiles or clinker brick, a thin polymer concrete slab that imitates various natural finishing materials. This layer can be painted in bulk or require painting after installation and filling of joints. There are a lot of options for thermal panels; you will always find several to choose from in your region.

This type of exterior decoration, in addition, radically solves the problem of thermal insulation of the frame. The only thing we recommend in this case is to glue the panels with polyurethane foam glue or polyurethane foam with maximum filling of the contact area with the wall.

Wet facade on a frame house

The “wet facade” technology is not so much different in design for frames, but has some features. Namely, it’s not worth it:

- glue polystyrene foam or basalt to OSB on cement mixtures– use polyurethane glue or foam;

- use wood screws and plastic washers for fastening large diameter, or caps from fungi - the fungus itself does not hold well in the slab; in the case of continuous installation on foam, you can remove the fasteners after its polymerization.

The remaining procedures of this technology are common to all types of houses:

- reinforcement with appropriate adhesives with alkali resistance plastic mesh in 1 or 2 layers;

- primer;

- applying the finishing plaster layer (fur coat, bark beetle, etc.);

- painting.

Plastering the walls of a frame house

When they talk about plastering a frame frame, they primarily mean plastering OSB. Let’s make a reservation right away - this option for exterior finishing can be used either in the case of covering all the seams between the panels with decorative slats (imitation half-timbering), or as temporary option protection of the facade until its final design.

No method of sealing seams will prevent cracks from appearing in them. Therefore, having chosen this type of finishing, do not waste any effort, time or money on the method described in many articles of gluing sickle tape, filling it with elastic sealants, etc.

Prime the walls with primer deep penetration, shoot the alkali-resistant mesh with a stapler and plaster with spatulas. It is better to use special elastic plaster for OSB - several Russian factories already produce this.

Other types of finishing of the facade of a frame house

Along with the previous method, other thin-layer coatings for OSB are often used - painting or coating with various polymer materials with or without the inclusion of fine stone powder.

Obviously, it is necessary to paint with compounds intended for application specifically to OSB. You will find a lot of such materials on the Internet, with their own patterns and installation technologies. Do not experiment with untested materials - it will cost you more.

Polymer compositions used for application to OSB have either an acrylate or polyurethane base. The first ones are less resistant to prolonged exposure to water and, even if painted in bulk, will last a long time with an additional water-repellent outer coating.

Fine-grained quartz most often serves as filling in them. It is more convenient to apply them with a Hopper pistol. Polyurethane compositions allow the addition of cement and are usually applied with spatulas in a fairly thick (up to 3 mm) layer. A larger filler can be pressed into them, such as dust-free granots or marble chips.

These types of finishing completely hide the OSB structure and give a solid look to the house. True, problems with seams between panels can also arise.